Preparing for an AC Mechanic interview requires a blend of technical expertise and strong problem-solving skills. This role is unique not only because it involves working with complex HVAC systems but also because it demands an understanding of customer service, as mechanics often interact directly with clients to diagnose and resolve issues. Proper interview preparation is crucial to showcase your technical knowledge, hands-on experience, and ability to work under pressure. This comprehensive guide will cover common interview questions, essential skills and qualifications, effective interview techniques, and tips to present yourself as the ideal candidate in the competitive field of HVAC services.

What to Expect in a AC Mechanic Interview

In an AC Mechanic interview, candidates can expect a combination of technical questions and practical assessments. Interviews are typically conducted by a hiring manager or a lead technician, who will evaluate both technical skills and problem-solving abilities. The process may begin with a phone screening followed by an in-person interview, which could include hands-on testing of HVAC systems. Candidates should be prepared to discuss previous experience, relevant certifications, and safety protocols. Overall, the interview aims to assess both competence and fit for the team.

AC Mechanic Interview Questions For Freshers

This set of interview questions is tailored for freshers aspiring to become AC Mechanics. Candidates should master fundamental concepts such as basic refrigeration principles, AC components, repair techniques, and safety protocols to excel in their interviews and start their careers in HVAC (Heating, Ventilation, and Air Conditioning).

1. What are the main components of an air conditioning system?

An air conditioning system typically consists of the following main components: compressor, condenser, expansion valve, and evaporator. The compressor circulates refrigerant through the system, the condenser releases heat, the expansion valve controls refrigerant flow, and the evaporator absorbs heat from the space to be cooled.

2. How does the refrigeration cycle work?

The refrigeration cycle involves four main processes: compression, condensation, expansion, and evaporation. The compressor compresses the refrigerant, raising its temperature and pressure. The refrigerant then releases heat in the condenser, changes state to liquid, passes through the expansion valve where it drops in pressure, and finally evaporates in the evaporator, absorbing heat from the indoor environment.

3. What is the purpose of the compressor in an AC system?

The compressor is a critical component in an AC system, responsible for compressing the refrigerant gas and increasing its pressure and temperature. This process allows the refrigerant to circulate throughout the system, enabling it to absorb heat from inside the building and release it outside, thus cooling the indoor air.

Build your resume in just 5 minutes with AI.

4. Can you explain the difference between R-22 and R-410A refrigerants?

- R-22: This is a hydrochlorofluorocarbon (HCFC) refrigerant that is being phased out due to its ozone depletion potential. It has been commonly used in older air conditioning systems.

- R-410A: This is a hydrofluorocarbon (HFC) refrigerant that does not deplete the ozone layer and is more energy-efficient. It is the preferred refrigerant in newer AC systems.

Understanding the differences between refrigerants is essential for proper maintenance and compliance with environmental regulations.

5. What are common symptoms of a refrigerant leak?

- Reduced cooling efficiency: The AC system struggles to cool the space effectively.

- Ice buildup: Ice may form on the evaporator coils or refrigerant lines.

- Hissing sound: A noticeable hissing or bubbling sound may indicate refrigerant escaping.

Identifying these symptoms early can prevent further damage to the system and ensure efficient operation.

6. How do you perform a basic AC system maintenance check?

A basic AC system maintenance check includes several steps: inspecting and cleaning or replacing air filters, checking the refrigerant levels, cleaning the condenser coils, inspecting electrical connections, and ensuring that the thermostat is functioning properly. Regular maintenance helps improve system efficiency and prolongs equipment life.

7. What safety precautions should be taken when working on AC systems?

- Always disconnect power: Ensure the power supply is turned off before starting any repair work.

- Use personal protective equipment (PPE): Wear safety goggles, gloves, and appropriate clothing.

- Handle refrigerants safely: Follow proper handling procedures to avoid exposure or leaks.

Adhering to safety protocols is crucial for the well-being of the technician and the proper functioning of the AC system.

8. What is the function of the expansion valve?

The expansion valve regulates the flow of refrigerant into the evaporator. It reduces the pressure of the refrigerant, allowing it to expand and cool before entering the evaporator coils. This process is vital for absorbing heat from the indoor air, maintaining efficient cooling performance.

9. Can you describe how to troubleshoot a non-functioning AC unit?

- Check the power supply: Ensure the unit is receiving power and that circuit breakers are not tripped.

- Inspect the thermostat: Verify that the thermostat is set to the desired temperature and is functioning correctly.

- Examine the air filters: Clogged filters can restrict airflow, causing cooling issues.

By following these troubleshooting steps, many common problems can be identified and resolved.

10. What is the role of the condenser in an AC system?

The condenser’s role is to dissipate heat from the refrigerant. It converts the high-pressure gas refrigerant from the compressor into a liquid state by releasing heat to the outside air. This process is essential for the refrigeration cycle to continue, as it prepares the refrigerant for the next phase of the cycle.

11. How can you improve the energy efficiency of an AC system?

- Regular maintenance: Performing routine checks and cleaning can enhance system efficiency.

- Seal ducts: Ensure that air ducts are well-sealed to prevent air leaks.

- Programmable thermostat: Use a programmable thermostat to optimize temperature settings based on occupancy.

Improving energy efficiency not only saves costs but also extends the lifespan of the equipment.

12. What tools are essential for an AC mechanic?

- Refrigerant gauge: To measure pressure and diagnose refrigerant levels.

- Multimeter: For checking electrical connections and troubleshooting electrical issues.

- Wrenches and screwdrivers: Basic hand tools for assembling and disassembling AC components.

Having the right tools is crucial for performing effective repairs and maintenance.

13. What is the significance of proper airflow in an AC system?

Proper airflow is vital for the efficiency and effectiveness of an air conditioning system. Insufficient airflow can lead to inadequate cooling, increased power consumption, and potential damage to the system. Ensuring that vents are unobstructed and filters are clean helps maintain optimal airflow.

14. How do you handle environmental regulations regarding refrigerants?

As an AC mechanic, it’s essential to stay informed about environmental regulations concerning refrigerants. This includes understanding the phase-out schedules for certain refrigerants and adhering to proper recovery and recycling procedures during repairs to minimize environmental impact and comply with legal standards.

15. What is the importance of the evaporator coil?

The evaporator coil is crucial for the cooling process in an AC system. It absorbs heat from the indoor air, causing the refrigerant inside the coil to evaporate and cool the air that is circulated back into the space. Proper functioning of the evaporator coil is essential for effective cooling and energy efficiency.

These questions are designed for freshers entering the AC Mechanic field and cover fundamental concepts they should master.

16. What are the main components of an air conditioning system?

An air conditioning system consists of several key components that work together to cool and dehumidify indoor air. The main components include:

- Compressor: The heart of the system, it compresses refrigerant and circulates it through the system.

- Condenser: This component releases heat from the refrigerant to the outside air, allowing it to cool and change from gas to liquid.

- Evaporator: Located inside the building, it absorbs heat from indoor air, causing the refrigerant to evaporate and cool the air.

- Expansion Valve: This regulates the flow of refrigerant into the evaporator, allowing it to expand and cool before entering the evaporator coil.

Understanding these components is crucial for diagnosing issues and performing maintenance on AC systems.

17. How do you troubleshoot a non-functioning air conditioning unit?

Troubleshooting a non-functioning air conditioning unit involves several steps to identify the problem. Here’s a systematic approach:

- Check the power supply: Ensure the unit is properly plugged in and the circuit breaker is not tripped.

- Inspect the thermostat: Verify that the thermostat is set to the cooling mode and the desired temperature is lower than the current room temperature.

- Examine the air filters: Dirty filters can restrict airflow; clean or replace them if necessary.

- Look for refrigerant leaks: Check for visible signs of refrigerant leaks and ensure the refrigerant levels are adequate.

By following these steps, you can diagnose common issues effectively and determine if professional repair is needed.

AC Mechanic Intermediate Interview Questions

In preparing for AC Mechanic interviews at the intermediate level, candidates should be familiar with both technical and practical aspects of air conditioning systems. Understanding refrigerants, system components, diagnostic procedures, and maintenance practices will be crucial for success in these interviews.

18. What is the purpose of the evaporator in an AC system?

The evaporator’s primary purpose is to absorb heat from the interior of the vehicle or building, thereby cooling the air. The refrigerant enters the evaporator as a low-pressure gas, absorbs heat from the surrounding air, and changes into a low-pressure vapor, which is then sent to the compressor. This process is essential for the overall cooling effect of the AC system.

19. Explain the function of the compressor in an AC system.

The compressor is a critical component that compresses the refrigerant gas into a high-pressure state. It increases the refrigerant’s pressure and temperature before sending it to the condenser. This process is vital as it enables the refrigerant to release its heat in the condenser, allowing the cooling cycle to continue.

20. What types of refrigerants are commonly used in AC systems?

- R-134a: A widely used refrigerant in automotive AC systems, known for its lower ozone depletion potential.

- R-410A: Commonly used in residential and commercial cooling systems, it is a hydrofluorocarbon (HFC) that replaces R-22.

- R-22: Previously common in residential systems, it is being phased out due to environmental concerns.

Understanding the properties and environmental impacts of these refrigerants is essential for AC mechanics to ensure compliance and efficiency in repairs.

21. How do you diagnose a refrigerant leak in an AC system?

Diagnosing a refrigerant leak can involve several methods, including visual inspection for oil stains, using electronic leak detectors, or applying a soap solution to suspect areas. A drop in cooling efficiency or pressure readings can also indicate a leak. Once identified, the leak must be repaired, and the system recharged with the correct amount of refrigerant.

22. What is the role of the condenser in an AC system?

The condenser’s role is to expel heat from the refrigerant as it transitions from a gas to a liquid. Located outside the vehicle or building, it cools the high-pressure refrigerant vapor that comes from the compressor. This process is essential for maintaining the efficiency of the AC system and ensuring effective cooling.

23. Describe the importance of regular maintenance on AC systems.

- Efficiency: Regular maintenance ensures the system operates at peak efficiency, reducing energy costs.

- Lifespan: Routine checks can prevent major issues, extending the lifespan of the AC unit.

- Air Quality: Maintenance helps in cleaning filters and ducts, improving indoor air quality.

Overall, regular maintenance is vital for functionality, efficiency, and health, saving time and repair costs in the long run.

24. How do you recharge an AC system?

To recharge an AC system, begin by connecting the refrigerant canister to the service ports. Using a manifold gauge set, check the low and high-pressure readings to determine the system’s needs. Open the canister valve and allow refrigerant to flow into the system while monitoring the pressures, ensuring not to overcharge. After recharging, check for leaks and test system performance.

25. What are common symptoms of a malfunctioning AC compressor?

- No cold air: The most obvious symptom, indicating a potential compressor failure.

- Strange noises: Unusual sounds like grinding or clattering can suggest internal damage.

- Visible damage: Leaks or physical damage to the compressor body can indicate failure.

Identifying these symptoms early can prevent further damage to the AC system and ensure timely repairs.

26. Explain the difference between a fixed and variable displacement compressor.

A fixed displacement compressor delivers a constant amount of refrigerant per revolution, making it less efficient under varying load conditions. In contrast, a variable displacement compressor adjusts its output based on the cooling demand, leading to improved efficiency and performance. Understanding these differences can help in diagnosing and selecting the right compressor for repairs or replacements.

27. What safety precautions should be taken when working with refrigerants?

- Personal Protective Equipment (PPE): Always wear gloves and goggles to protect against refrigerant exposure.

- Ventilation: Work in well-ventilated areas to avoid inhaling refrigerant gases.

- Proper Disposal: Follow regulations for the safe disposal of refrigerants to minimize environmental impact.

These precautions are crucial to ensure safety for technicians and compliance with environmental regulations.

28. What is the significance of the expansion valve in an AC system?

The expansion valve controls the flow of refrigerant into the evaporator, allowing it to expand and cool as it enters. This component is essential for maintaining the correct pressure and temperature of the refrigerant, which directly affects the efficiency and effectiveness of the cooling process.

29. How can you test the efficiency of an AC system?

Testing the efficiency of an AC system can involve measuring the temperature difference between the air entering and exiting the evaporator, checking refrigerant pressures, and evaluating the compressor’s performance. A significant temperature drop indicates effective cooling, while abnormal pressure readings can signal issues needing attention.

30. What are some common causes of AC system failure?

- Refrigerant leaks: The most common cause, leading to loss of cooling capability.

- Electrical issues: Faulty wiring or connections can prevent the system from operating.

- Clogged filters: Dirty filters can restrict airflow, causing inefficiency and overheating.

Understanding these causes can help technicians in diagnosing and preventing future failures, improving overall system reliability.

These questions are designed for intermediate-level AC mechanics, focusing on practical applications and best practices in the field.

33. What are the common causes of AC system failure, and how can they be diagnosed?

Common causes of AC system failure include refrigerant leaks, compressor malfunctions, electrical issues, and clogged filters. To diagnose these problems, the following methods can be employed:

- Refrigerant Leak Detection: Use a leak detector or soapy water to identify leaks in the system.

- Compressor Check: Listen for unusual noises and check if the compressor is cycling properly.

- Electrical Inspection: Check fuses, relays, and wiring for signs of damage or wear.

- Filter Inspection: Ensure that the air filters are clean and not obstructing airflow.

By systematically checking these components, mechanics can effectively identify and resolve AC system failures.

34. How do you properly charge an AC system, and what steps should be taken to ensure efficiency?

Charging an AC system involves adding refrigerant to the system to achieve optimal performance. The following steps should be followed:

- Determine the Correct Refrigerant Type: Ensure the right refrigerant is used as specified by the manufacturer.

- Connect Manifold Gauges: Attach the gauges to the service ports, ensuring the system is off before connecting.

- Vacuum the System: Use a vacuum pump to remove moisture and air from the system.

- Add Refrigerant: Slowly add refrigerant while monitoring the gauges to reach the specified pressure.

- Check System Performance: After charging, check the system’s temperature and pressure to ensure proper operation.

By following these steps, mechanics can ensure that the AC system operates efficiently and effectively, prolonging its lifespan.

AC Mechanic Interview Questions for Experienced

This set of interview questions for experienced AC Mechanics delves into advanced topics such as system diagnostics, energy efficiency optimization, refrigerant management, and leadership skills. These questions are designed to evaluate the depth of knowledge and problem-solving abilities in real-world situations within the HVAC industry.

35. What are the key factors to consider when optimizing an HVAC system for energy efficiency?

Key factors for optimizing HVAC systems include:

- Proper sizing of equipment: Ensuring that the system is not oversized or undersized for the space.

- Regular maintenance: Conducting routine inspections and servicing to maintain system efficiency.

- Airflow management: Ensuring proper duct design and sealing to minimize leaks and enhance airflow.

- Use of programmable thermostats: Implementing smart controls to optimize heating and cooling schedules.

- Energy-efficient equipment: Choosing high SEER-rated units to reduce energy consumption.

By addressing these factors, HVAC systems can significantly reduce energy costs and improve overall performance.

36. Explain the importance of proper refrigerant management in HVAC systems.

Proper refrigerant management is crucial for several reasons:

- Environmental impact: Using the correct type and amount of refrigerant minimizes greenhouse gas emissions.

- System efficiency: Proper refrigerant levels ensure optimal cooling performance and energy efficiency.

- Regulatory compliance: Adhering to regulations regarding refrigerant types and handling to avoid penalties.

- Leak prevention: Regular checks and maintenance to prevent leaks which can lead to system failure and increased operational costs.

Effective refrigerant management ultimately leads to a more sustainable and cost-effective HVAC operation.

37. What diagnostic tools do you commonly use to troubleshoot HVAC issues?

Common diagnostic tools include:

- Multimeter: For electrical diagnostics and measuring voltage, current, and resistance.

- Manifold gauge set: To measure refrigerant pressures and diagnose cooling performance.

- Thermometers: To check temperature differentials across coils and ducts.

- Leak detectors: For identifying refrigerant leaks in the system.

- Smart diagnostic apps: Utilizing technology for detailed system analysis and reporting.

Using these tools effectively helps in accurately diagnosing issues and implementing timely repairs.

38. Describe a situation where you had to mentor a junior technician. What approach did you take?

In mentoring a junior technician, I adopted a hands-on approach by first assessing their current skill level. I then provided structured training sessions covering key concepts, safety protocols, and practical skills. I encouraged questions and offered real-world scenarios to apply their knowledge. Additionally, I set up a feedback loop where we reviewed progress regularly, ensuring they felt supported and confident in their development.

39. How do you stay current with the latest HVAC technologies and regulations?

Staying current involves several strategies:

- Continuous education: Attending workshops, webinars, and training sessions on new technologies.

- Networking: Engaging with industry professionals through associations and forums to share knowledge.

- Reading industry publications: Keeping up with trade journals and newsletters for updates on regulations and innovations.

- Certification programs: Pursuing certifications that focus on emerging trends and technologies in HVAC.

By combining these methods, I ensure that my skills and knowledge remain relevant and up-to-date.

40. What design patterns do you find most useful in HVAC system layout?

Some useful design patterns in HVAC systems include:

- Modular design: Allows for flexibility and scalability in system layout.

- Zone control: Facilitates targeted heating/cooling, improving energy efficiency and comfort.

- Load calculation patterns: Ensures that systems are designed based on accurate load requirements for efficiency.

These patterns help in creating effective and efficient HVAC systems tailored to specific building needs.

41. Can you explain the process of conducting a load calculation for an HVAC system?

The load calculation process typically involves:

- Gathering data: Collecting information on the building’s size, layout, insulation, and window types.

- Using software or manual methods: Applying methods such as Manual J calculations to determine heating and cooling loads.

- Considering external factors: Accounting for local climate, sun exposure, and occupancy levels.

- Documenting findings: Providing a detailed report that outlines the calculated loads to guide equipment selection.

This process ensures that the HVAC system is designed to meet the specific needs of the building efficiently.

42. What are the common causes of HVAC system failures, and how do you address them?

Common causes of HVAC system failures include:

- Lack of maintenance: Regular inspections and cleanings can prevent many issues.

- Electrical problems: Ensuring all electrical connections are secure and components are functioning properly prevents failures.

- Refrigerant leaks: Prompt detection and repair of leaks are essential to maintain system performance.

- Clogged filters: Regularly replacing or cleaning filters helps improve airflow and efficiency.

Addressing these issues through preventive maintenance and timely repairs can significantly reduce the risk of system failures.

43. How do you approach system troubleshooting when faced with a complex issue?

When troubleshooting a complex HVAC issue, I follow a systematic approach:

- Gather information: Speak with clients to understand symptoms and history of the system.

- Perform diagnostics: Use appropriate tools to assess system performance and identify anomalies.

- Isolate the problem: Narrow down potential causes by testing individual components.

- Implement solutions: Apply fixes based on findings and retest the system to ensure resolution.

This structured approach helps in efficiently resolving complex issues while minimizing downtime.

44. What are the best practices for ensuring safety while working on HVAC systems?

Best practices for HVAC safety include:

- Personal Protective Equipment (PPE): Always wear appropriate safety gear such as gloves, goggles, and masks.

- Lockout/tagout procedures: Ensure that systems are de-energized before performing maintenance or repairs.

- Awareness of refrigerants: Be knowledgeable about the properties and handling guidelines of refrigerants used.

- Proper lifting techniques: Use safe lifting practices to prevent injuries when handling heavy equipment.

Adhering to these practices is essential for maintaining a safe working environment in HVAC operations.

Build your resume in 5 minutes

Our resume builder is easy to use and will help you create a resume that is ATS-friendly and will stand out from the crowd.

45. Describe how you would implement a preventive maintenance program for HVAC systems.

Implementing a preventive maintenance program involves:

- Establishing a schedule: Create a regular maintenance schedule based on manufacturer recommendations and system usage.

- Training staff: Ensure all technicians are trained on maintenance procedures and safety protocols.

- Documenting procedures: Develop checklists for routine inspections and tasks to ensure consistency.

- Monitoring performance: Track system performance and maintenance activities to identify trends and areas for improvement.

This proactive approach helps extend the lifespan of HVAC systems and improves reliability.

How to Prepare for Your AC Mechanic Interview

Preparing for an AC Mechanic interview involves understanding both technical skills and soft skills required for the role. This includes hands-on experience, knowledge of AC systems, and the ability to communicate effectively with customers and team members.

- Familiarize yourself with common AC systems: Review the different types of air conditioning systems, such as central, split, and window units. Understand their components, operation, and maintenance requirements to demonstrate your technical expertise during the interview.

- Brush up on refrigerant handling: Know the various types of refrigerants, their properties, and safety protocols for handling them. Being knowledgeable in refrigerant recovery and recycling can set you apart as a responsible and compliant technician.

- Review electrical basics: Understand the electrical components of AC systems, including capacitors, contactors, and circuit boards. Be prepared to discuss troubleshooting techniques and how to diagnose electrical issues that may arise in AC units.

- Prepare for hands-on assessments: Some interviews may include practical tests. Practice common repairs and maintenance tasks, like replacing filters, checking refrigerant levels, or cleaning coils, to showcase your hands-on skills and problem-solving abilities.

- Understand HVAC regulations: Familiarize yourself with local and national HVAC regulations, including safety standards and building codes. Show your awareness of compliance issues and how they impact daily operations in your interview.

- Develop customer service skills: As an AC Mechanic, you’ll interact with clients. Practice explaining technical concepts in layman’s terms and handling customer inquiries or complaints. Highlight your ability to provide exceptional service during the interview.

- Research the company: Learn about the company’s mission, values, and the services they offer. Tailor your responses to demonstrate how your skills align with their needs, showing your enthusiasm and fit for the role during the interview.

Common AC Mechanic Interview Mistakes to Avoid

When interviewing for an AC Mechanic position, avoiding common mistakes can significantly enhance your chances of success. Understanding these pitfalls can help you present yourself more effectively and demonstrate your qualifications for the role.

- Inadequate Preparation: Failing to research the company and its services can lead to uninformed answers. Understand the types of air conditioning systems they work with and any specialties they may have.

- Neglecting Safety Protocols: Not emphasizing safety practices in your responses can be detrimental. It’s crucial to demonstrate your understanding of safety measures and compliance with industry regulations.

- Lack of Practical Examples: Avoid speaking only in generalities. Providing specific examples of past experiences, particularly those that showcase your problem-solving skills, can make you stand out.

- Ignoring Soft Skills: Technical expertise is important, but neglecting to highlight communication and teamwork skills can weaken your application. Employers value mechanics who can work well with customers and colleagues.

- Failure to Ask Questions: Not asking insightful questions can indicate a lack of interest. Prepare questions that show your enthusiasm about the role and the company’s future.

- Poor Time Management: Arriving late or spending too much time on certain questions can reflect poorly on your professionalism. Arrive early and practice concise responses to maintain a good flow.

- Not Demonstrating Continuous Learning: The HVAC industry evolves constantly. Failing to mention your commitment to ongoing education or certifications can suggest stagnation in your skills.

- Overlooking Follow-Up: Not sending a thank-you note or follow-up email can be a missed opportunity to reinforce your interest. A well-crafted follow-up shows professionalism and appreciation for the interviewer’s time.

Key Takeaways for AC Mechanic Interview Success

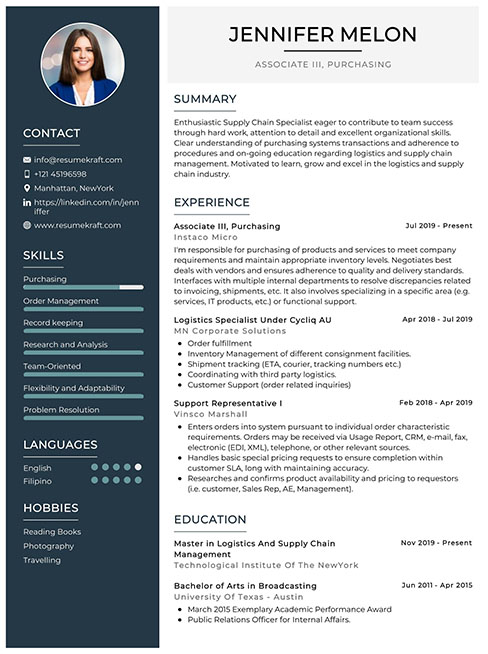

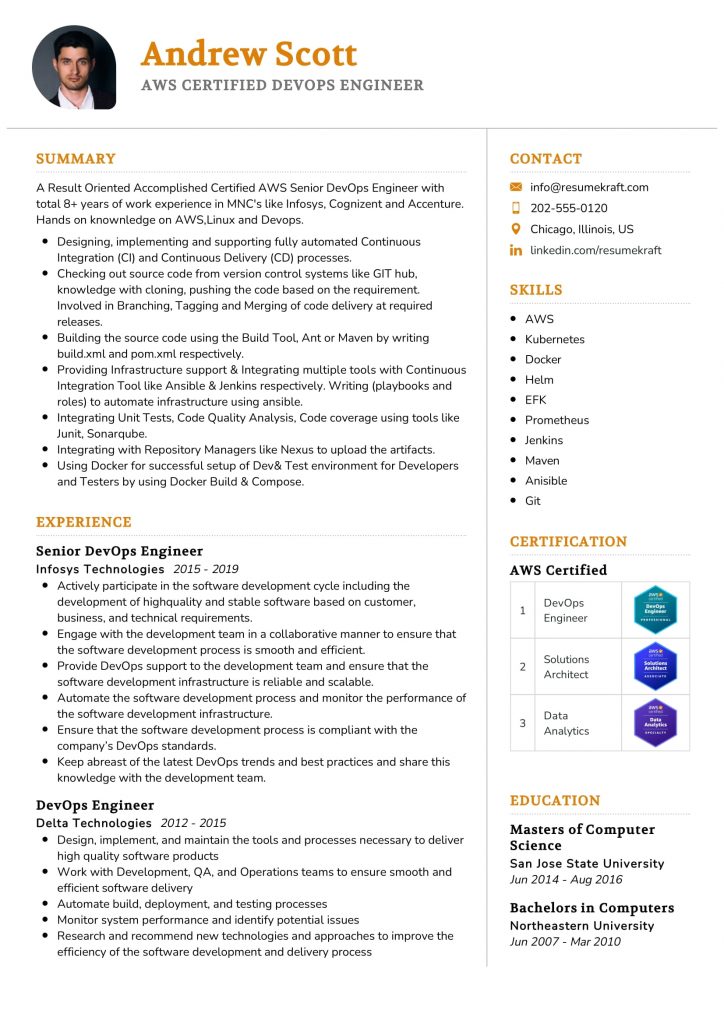

- Prepare a polished resume using an AI resume builder to ensure clarity and professionalism. Highlight relevant skills and experience that align with the AC mechanic position.

- Utilize resume templates to create a visually appealing and organized format. A well-structured resume can make a strong first impression on potential employers.

- Showcase your experience with impactful resume examples that demonstrate your practical skills and accomplishments in the automotive field. This will help you stand out among other candidates.

- Craft tailored cover letters that express your passion for the AC mechanic role and detail how your experience meets the job requirements. This adds a personal touch to your application.

- Engage in mock interview practice to refine your responses and build confidence. This preparation will help you articulate your skills effectively during the actual interview.

Frequently Asked Questions

1. How long does a typical AC Mechanic interview last?

A typical AC Mechanic interview usually lasts between 30 minutes to an hour. This time frame allows the interviewer to assess your technical skills, experience, and problem-solving abilities, while also giving you a chance to ask questions. Be prepared for both technical questions related to HVAC systems and behavioral questions that assess your work ethic and teamwork. Being concise and focused in your responses will help you make a positive impression within this time frame.

2. What should I wear to a AC Mechanic interview?

For an AC Mechanic interview, it’s best to dress in business casual attire. This typically means wearing clean, neat clothing such as a collared shirt and slacks or nice jeans. Avoid overly casual items like t-shirts or shorts. You want to present yourself as professional, yet approachable. It’s also a good idea to wear closed-toe shoes that are in good condition, as this reflects your attention to detail and respect for the workplace environment.

3. How many rounds of interviews are typical for a AC Mechanic position?

Typically, there are one to three rounds of interviews for an AC Mechanic position. The first round is often a phone or video interview to gauge your basic qualifications and fit for the role. Subsequent rounds may involve in-person interviews, possibly including hands-on assessments to evaluate your technical skills. Some companies may also include a final round with management or technical supervisors to discuss your experience and how you would fit into their team.

4. Should I send a thank-you note after my AC Mechanic interview?

Yes, sending a thank-you note after your AC Mechanic interview is a good practice. It shows your appreciation for the opportunity and reinforces your interest in the position. A brief email or handwritten note within 24 hours of the interview is ideal. In your message, thank the interviewer for their time, mention something specific discussed during the interview, and express your enthusiasm for the role. This can help you leave a lasting impression and stand out among other candidates.