Preparing for a carpenter interview requires a blend of practical skills and the ability to communicate your craftsmanship effectively. This role is unique as it combines artistry with technical expertise, necessitating a deep understanding of materials, tools, and construction techniques. Proper interview preparation is vital, as it helps you showcase your experience and problem-solving skills while demonstrating your passion for the trade. In this comprehensive guide, we will cover common interview questions, essential skills and qualifications, tips for presenting your portfolio, and strategies to make a lasting impression. Whether you’re a seasoned carpenter or a newcomer, this guide will equip you for success in your interview.

What to Expect in a Carpenter Interview

In a Carpenter interview, candidates can expect a combination of practical assessments and verbal questioning. Typically, interviews may be conducted by a hiring manager or a senior carpenter who will evaluate both technical skills and experience. The structure often includes an initial discussion about the candidate’s background, followed by questions on carpentry techniques, safety practices, and problem-solving scenarios. Candidates may also be asked to demonstrate their skills through hands-on tasks, such as measuring, cutting, or assembling materials, to showcase their craftsmanship and attention to detail.

Carpenter Interview Questions For Freshers

Carpenter interview questions for freshers often focus on fundamental skills, tools, and techniques essential for the trade. Candidates should master basic woodworking principles, safety practices, and the use of various hand and power tools, as well as measurement and layout techniques.

1. What are the basic tools used by a carpenter?

Carpenters use a variety of tools essential for their work. Basic tools include a tape measure for accurate measurements, a hammer for driving nails, saws (such as hand saws and power saws) for cutting wood, chisels for shaping, and a square to ensure right angles. Safety gear like goggles and gloves is also crucial for protection.

2. What is the importance of measuring accurately in carpentry?

Accurate measurements are vital in carpentry to ensure that all pieces fit together correctly. Miscalculations can lead to wasted materials and time, resulting in costly mistakes. Precise measurements ensure structural integrity and the overall quality of the finished project, whether it’s furniture, framing, or cabinetry.

3. Can you explain the difference between hardwood and softwood?

- Hardwood: Comes from deciduous trees and is generally denser and more durable, making it suitable for furniture and flooring.

- Softwood: Comes from coniferous trees and is lighter, often easier to work with, and typically used for construction framing and outdoor projects.

Understanding the difference is essential for selecting the right material for specific tasks.

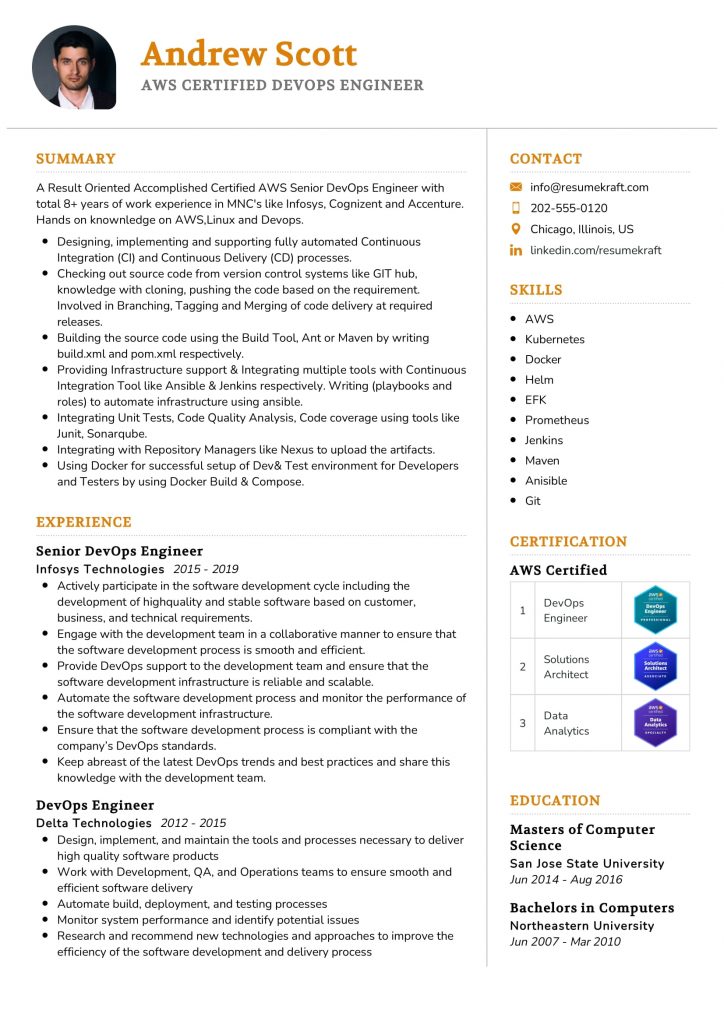

Build your resume in just 5 minutes with AI.

4. What safety precautions should a carpenter take while working?

- Wear protective gear such as goggles, gloves, and dust masks to prevent injuries.

- Ensure tools are well-maintained and used correctly to avoid accidents.

- Keep the work area organized to prevent trips and falls.

- Be aware of surroundings and potential hazards, especially when operating power tools.

Prioritizing safety helps prevent injuries and ensures a productive working environment.

5. How do you select the right type of wood for a project?

Selecting the right wood depends on the project requirements, including durability, appearance, and cost. Consider factors like the wood’s density, grain pattern, and resistance to moisture and insects. For example, oak is great for furniture due to its strength, while pine is often chosen for framing due to its affordability.

6. What is a miter joint, and where is it commonly used?

A miter joint is formed by cutting two pieces of wood at an angle, typically 45 degrees, to create a corner joint. It is commonly used in frames, moldings, and furniture to provide a clean and finished look. Proper alignment and accurate cutting are crucial for a strong miter joint.

7. Describe the process of framing a wall.

Framing a wall involves several steps: first, measure and mark the layout on the floor. Next, cut the bottom and top plates to size, then attach them to the floor and ceiling. Install vertical studs between the plates, ensuring they are spaced evenly (typically 16 or 24 inches apart). Finally, secure everything with nails or screws, and check for plumb and level.

8. What is the function of a level in carpentry?

A level is a tool used to determine whether a surface is horizontal (level) or vertical (plumb). It consists of a sealed tube with liquid and an air bubble. When the bubble is centered between the lines, the surface is properly aligned. Levels are essential for ensuring that structures are built correctly, preventing future issues.

9. What are wood knots, and how do they affect wood quality?

Wood knots are natural imperfections that occur where branches join the trunk of a tree. They can affect the wood’s strength, appearance, and workability. While some knots can add character to finished products, excessive knots might weaken the wood or complicate cutting and finishing processes.

10. Explain what a dado joint is and its application.

A dado joint is a woodworking joint created by cutting a groove across the grain of a piece of wood to fit another piece into it. This joint is commonly used in shelving and cabinetry, providing a strong connection that increases stability. Dado joints can be cut using a table saw or router.

11. How do you maintain and care for your tools?

- Regularly clean tools after use to prevent rust and buildup.

- Sharpen blades and bits as needed to ensure efficient cutting.

- Store tools in a dry, organized manner to avoid damage.

- Inspect tools for wear and replace or repair them as necessary.

Proper maintenance extends the life of tools and ensures they perform effectively.

12. What is the purpose of wood finishes?

Wood finishes serve several purposes, including protecting the wood from moisture, stains, and wear. They enhance the wood’s appearance by adding color and depth while providing a smooth surface. Common finishes include varnish, lacquer, oil, and polyurethane. Choosing the right finish is crucial for the longevity and aesthetics of the project.

13. Can you explain the term ‘grain direction’ in woodworking?

Grain direction refers to the alignment of wood fibers in a piece of lumber. Understanding grain direction is essential as it affects how wood reacts to cutting, sanding, and finishing. Cutting against the grain can lead to splintering, while cutting with the grain produces smoother surfaces. Proper handling according to grain direction ensures better results in woodworking projects.

Carpenter Intermediate Interview Questions

This set of Carpenter interview questions is tailored for intermediate candidates, focusing on essential skills and knowledge required for mid-level positions. Candidates should be familiar with advanced techniques, project management, and safety practices to effectively handle more complex carpentry tasks.

14. What are the key differences between hardwood and softwood?

Hardwoods come from deciduous trees and typically have a denser structure, making them more durable and suitable for high-quality furniture and flooring. Softwoods, derived from coniferous trees, are generally lighter, more affordable, and easier to work with. Hardwoods often showcase intricate grain patterns, while softwoods are more uniform, making them popular for construction and crafting.

15. How do you select the right wood for a specific project?

Selecting the right wood involves considering the project’s requirements, such as strength, appearance, and resistance to environmental factors. Factors to evaluate include:

- Purpose: Determine whether the wood will be used for structural support, aesthetics, or both.

- Durability: Assess the wood’s ability to withstand wear, moisture, and pests based on its intended use.

- Cost: Consider the budget constraints and the availability of different wood types.

Ultimately, matching the wood’s properties with the project needs ensures functionality and longevity.

16. What safety precautions should you take when using power tools?

When using power tools, it’s crucial to follow safety guidelines to prevent accidents. Key precautions include:

- Personal Protective Equipment (PPE): Always wear safety goggles, gloves, and ear protection.

- Tool Inspection: Regularly check tools for damage or defects before use.

- Work Area Safety: Keep the work area clean and free of hazards to ensure safe operation.

These measures help minimize risks and ensure a safe working environment.

17. How do you properly measure and cut wood for a project?

Accurate measurement and cutting are critical in carpentry. Start by measuring twice to ensure accuracy before making any cuts. Use a square to mark straight lines and a sharp saw for clean edges. It’s also important to consider the kerf (the width of the saw blade) when measuring, as this can affect the final dimensions of your pieces.

18. Describe the process of joining two pieces of wood together.

Joining two pieces of wood can be achieved through various methods, including:

- Wood Glue: Apply glue on the edges, clamp the pieces together, and allow it to cure for a strong bond.

- Screws: Pre-drill holes to prevent splitting, then drive screws through one piece into the other.

- Dowels: Drill matching holes in both pieces, insert dowels with glue, and align them to create a sturdy joint.

Choosing the right method depends on the project requirements and the desired strength of the joint.

19. What is the purpose of using clamps in woodworking?

Clamps are essential tools in woodworking for holding pieces of wood together securely during gluing, assembly, or drying processes. They ensure that joints remain aligned and stable, helping to prevent gaps and misalignment. Using clamps can significantly improve the quality of finished projects and reduce the risk of errors.

20. Explain the importance of finishing in carpentry.

Finishing is crucial in carpentry as it enhances the wood’s appearance, protects it from moisture, UV rays, and wear, and prolongs its lifespan. Common finishing techniques include sanding, staining, sealing, and applying varnish or paint. A well-executed finish can elevate the aesthetic appeal of a project while providing necessary protection against environmental damage.

21. What are some common types of wood joints used in furniture making?

Common wood joints include:

- Butt Joint: Simple and easy to make; used for basic constructions.

- Dado Joint: A groove cut into one piece of wood to receive another, providing strength and stability.

- <strong=Miter Joint: Used for corners, where two pieces are cut at an angle and joined together.

- <strong=Mortise and Tenon: A strong joint where a protruding tenon fits into a mortise hole.

Each joint has specific applications and strengths, making it important to choose the right one for the project.

22. How do you handle wood defects when working on a project?

Handling wood defects involves assessing the type and extent of the defect, such as knots, splits, or warping. Strategies include:

- Cutting Around Defects: Remove defective areas by cutting them out and replacing them with sound wood.

- Using Filler: Fill small defects with wood filler to create a smooth surface.

- Strategic Placement: Position defects in less visible areas to minimize their impact on the overall appearance.

Addressing wood defects appropriately ensures the integrity and aesthetics of the final product.

23. What is the role of a carpenter in a construction project?

A carpenter plays a vital role in construction, responsible for framing, installing structures, and finishing work. This includes tasks such as building walls, installing doors and windows, and crafting cabinetry. Carpenters must collaborate with other trades, interpret blueprints, and ensure that all work meets safety standards and building codes. Their expertise is crucial for the project’s overall success.

24. Describe how to create a custom shelving unit.

Creating a custom shelving unit involves several steps:

- Design: Plan the dimensions and layout, considering the space available.

- Material Selection: Choose appropriate wood based on the weight it needs to support and desired aesthetics.

- Construction: Cut wood to size, assemble using appropriate joints, and sand surfaces for a smooth finish.

- Finishing: Apply stain or paint to enhance appearance and protect the wood.

Following these steps ensures a functional and visually appealing shelving unit tailored to specific needs.

25. What are some best practices for maintaining tools and equipment?

Maintaining tools and equipment is essential for safety and longevity. Best practices include:

- Regular Cleaning: Clean tools after each use to remove dust and debris.

- Lubrication: Regularly lubricate moving parts to prevent rust and ensure smooth operation.

- Proper Storage: Store tools in a dry, organized space to prevent damage.

Consistent maintenance not only enhances tool performance but also promotes safety during use.

Carpenter Interview Questions for Experienced

This set of Carpenter interview questions focuses on advanced topics relevant for experienced professionals. The questions cover areas such as architectural design, optimization techniques, scalability considerations, design patterns, and leadership skills, ensuring that candidates can demonstrate their expertise and ability to mentor others in the field.

27. How do you ensure the structural integrity of a complex woodworking project?

Ensuring structural integrity in complex woodworking projects involves several key practices: using quality materials, understanding load distribution, and applying appropriate joinery techniques. It’s essential to calculate the weight and stress factors that the structure will endure. Regularly performing checks during the assembly process and adhering to building codes also contribute to maintaining integrity throughout the project lifecycle.

28. Can you explain the importance of using design patterns in carpentry?

Design patterns in carpentry refer to established solutions for common problems encountered in woodworking. Their importance includes:

- Efficiency: By reusing proven techniques, craftsmen can save time and reduce errors.

- Consistency: Design patterns help maintain uniformity in projects, ensuring high-quality results.

- Scalability: When projects grow in complexity, design patterns facilitate easier adaptations and modifications.

By leveraging design patterns, carpenters can enhance their workflow and the overall quality of their work.

29. Describe an experience where you had to optimize a woodworking process.

In one project, I noticed that the cutting phase was taking longer than necessary due to frequent tool changes. To optimize the process, I implemented a system where similar cuts were grouped together, reducing downtime. Additionally, I trained my team on proper tool maintenance to ensure efficiency. As a result, we increased our output by 20% while maintaining quality standards.

30. What strategies do you use to mentor junior carpenters?

Mentoring junior carpenters involves several effective strategies:

- Hands-On Training: I engage them in practical projects, allowing them to learn through experience.

- Feedback: Providing constructive feedback on their work helps them improve their skills.

- Knowledge Sharing: I organize workshops to share insights on advanced techniques and safety practices.

These strategies not only enhance their skills but also build their confidence in the craft.

31. How do you assess the scalability of a woodworking project?

Assessing scalability in woodworking projects involves analyzing several factors:

- Material Availability: Ensuring that the materials needed can be sourced in larger quantities.

- Design Complexity: Evaluating if the design can be replicated easily without loss of quality.

- Resource Management: Assessing whether the current workforce can handle increased production demands.

This comprehensive assessment helps in planning for future growth and maintaining quality standards.

32. What role does sustainability play in your carpentry projects?

Sustainability is integral to my carpentry projects. I prioritize using reclaimed wood and eco-friendly finishes to minimize environmental impact. Additionally, I implement efficient waste management practices, such as recycling scrap materials. Educating clients about sustainable options also helps promote environmentally responsible decisions. This approach not only benefits the planet but also appeals to a growing market of eco-conscious consumers.

Build your resume in 5 minutes

Our resume builder is easy to use and will help you create a resume that is ATS-friendly and will stand out from the crowd.

33. Can you give an example of a challenging project and how you overcame obstacles?

One challenging project involved creating custom cabinetry for a uniquely shaped kitchen. The main obstacle was fitting the cabinets into irregular spaces. To overcome this, I used advanced measuring techniques and created detailed templates. Collaboration with the client was crucial, as I regularly sought feedback during the design process. The project was completed successfully, exceeding client expectations and showcasing our flexibility in design.

34. How do you stay updated with the latest trends and technologies in carpentry?

Staying updated with trends and technologies in carpentry involves several approaches:

- Continuous Learning: I attend workshops, seminars, and trade shows dedicated to woodworking.

- Networking: Engaging with other professionals through forums and social media allows me to exchange ideas.

- Research: Regularly reading industry publications and online resources helps me keep abreast of innovations.

This commitment to learning ensures I can incorporate the best practices and technologies into my work.

35. What safety protocols do you implement on the job site?

Implementing safety protocols on the job site is crucial. I ensure that all team members wear appropriate personal protective equipment (PPE), including goggles, gloves, and ear protection. Regular safety meetings are held to discuss potential hazards and best practices. Additionally, I conduct thorough equipment checks to ensure all tools are functioning properly. Encouraging a culture of safety awareness significantly reduces the risk of accidents.

36. How do you approach project management in carpentry?

Effective project management in carpentry involves several key components:

- Planning: I create detailed project plans outlining timelines, budgets, and resource allocation.

- Communication: Maintaining clear communication with clients and team members ensures everyone is aligned.

- Monitoring Progress: Regularly reviewing project status and making necessary adjustments helps keep projects on track.

This structured approach allows me to deliver high-quality results while adhering to deadlines and budgets.

How to Prepare for Your Carpenter Interview

Preparing effectively for a Carpenter interview involves understanding both the technical skills required and the practical applications of woodworking. Candidates should focus on demonstrating their craftsmanship, safety knowledge, and problem-solving abilities to impress potential employers.

- Review Basic Carpentry Skills: Brush up on essential carpentry techniques, such as measuring, cutting, and joining materials. Familiarize yourself with different types of wood and tools commonly used in the industry to demonstrate your hands-on experience during the interview.

- Prepare Your Portfolio: Compile a portfolio showcasing your past projects, including photographs and descriptions. Highlight specific techniques you used and any challenges you overcame. This tangible evidence of your skills can set you apart from other candidates.

- Understand Safety Regulations: Familiarize yourself with safety regulations and best practices in carpentry. Be prepared to discuss how you ensure a safe working environment and your experience with personal protective equipment (PPE) to demonstrate your commitment to safety.

- Practice Problem-Solving Scenarios: Anticipate questions about how you handle challenges on the job, such as unexpected material issues or design changes. Prepare specific examples that showcase your critical thinking and adaptability in real-world situations.

- Know the Company: Research the company you are interviewing with, including their projects, values, and work culture. Tailor your responses to align with their goals and demonstrate your enthusiasm for being part of their team.

- Brush Up on Math Skills: Carpentry often requires math for measurements and calculations. Review basic geometry and arithmetic skills to confidently answer questions related to project planning and material estimation during the interview.

- Prepare Questions for the Interviewer: Have thoughtful questions ready to ask the interviewer about their team, projects, and expectations. This shows your genuine interest in the position and helps you evaluate if the company is the right fit for you.

Common Carpenter Interview Mistakes to Avoid

When interviewing for a Carpenter position, candidates often make critical mistakes that can hinder their chances of success. Understanding these common pitfalls can help you present your skills and experience effectively, showcasing your qualifications for the job.

- Not Researching the Company: Failing to understand the company’s projects and values can make you appear uninterested. Researching allows you to tailor your responses and demonstrate your alignment with the company’s goals.

- Neglecting Safety Practices: Carpenters must prioritize safety. Not discussing safety procedures or showcasing your commitment to maintaining a safe work environment can raise red flags for employers.

- Underestimating Communication Skills: Carpenters often work in teams and must communicate effectively. Not highlighting your communication skills may suggest you can’t collaborate well with others on-site.

- Inadequate Skill Demonstration: Assuming your experience speaks for itself without providing specific examples or evidence can leave the interviewer unconvinced of your capabilities. Always be ready to showcase your skills.

- Being Vague About Experience: Generalizing your work history can weaken your candidacy. Provide specific details about your past projects, tools used, and techniques learned to give a clearer picture of your expertise.

- Ignoring Questions About Challenges: Carpenters face various challenges on the job. Not being prepared to discuss how you’ve overcome difficulties can suggest a lack of problem-solving skills.

- Not Asking Questions: An interview is a two-way street. Failing to ask insightful questions about the role or company can signal disinterest. Prepare thoughtful questions to demonstrate engagement and curiosity.

- Being Unprepared for Technical Questions: Employers may ask technical questions related to carpentry tools and techniques. Not being ready to answer these can indicate a lack of depth in your trade knowledge.

Key Takeaways for Carpenter Interview Success

- Highlight your practical experience and technical skills in carpentry, emphasizing specific projects you’ve completed. Use clear examples to demonstrate your craftsmanship and problem-solving abilities.

- Research the company and its projects to tailor your responses and show genuine interest. Understanding their work will help you connect your skills to their needs effectively.

- Prepare thoughtful questions about the company’s culture, safety practices, and team dynamics. This demonstrates your commitment and helps you assess if the workplace aligns with your values.

- Develop an interview preparation checklist to ensure you cover essential topics, including tools, techniques, and safety regulations relevant to the carpentry role you are applying for.

- Engage in mock interview practice with a friend or mentor to refine your answers and gain confidence. This will help you articulate your skills clearly during the actual interview.

Frequently Asked Questions

1. How long does a typical Carpenter interview last?

A typical Carpenter interview lasts between 30 to 60 minutes. The duration can vary depending on the company and the complexity of the position. During this time, interviewers usually assess your technical skills, experience, and knowledge of carpentry techniques. Be prepared for practical questions or even a skills demonstration, as employers want to ensure you possess the necessary abilities to perform the job effectively.

2. What should I wear to a Carpenter interview?

For a Carpenter interview, it’s best to dress in a way that balances professionalism with practicality. Wear clean, well-fitted work attire such as durable pants and a collared shirt. Avoid overly casual clothing like t-shirts or shorts. If you’re meeting at a job site, consider wearing steel-toed boots and a work jacket to reflect your familiarity with the trade, while still looking neat and presentable for the interview setting.

3. How many rounds of interviews are typical for a Carpenter position?

Typically, there are one to two rounds of interviews for a Carpenter position. The first round often involves a general interview where your skills and experience are discussed. If you progress to a second round, it may include a practical assessment or a meeting with the hiring manager and team members. Some companies may conduct additional interviews for specialized roles or project-based positions, depending on their hiring process.

4. Should I send a thank-you note after my Carpenter interview?

Yes, sending a thank-you note after your Carpenter interview is a good practice. It shows appreciation for the interviewer’s time and reinforces your enthusiasm for the position. Keep the note concise, mentioning specific points from the interview that you found valuable or interesting. A well-crafted thank-you note can leave a positive impression and may differentiate you from other candidates competing for the same role.