Inventory management is a crucial aspect of any business that handles physical products. Effective inventory management can drastically reduce holding costs, improve customer satisfaction, and increase overall operational efficiency. If you’re aiming for a job in this field, you must be prepared to answer some tough interview questions that test both your technical and interpersonal skills. In this article, we’re going to walk you through 19 of the most commonly asked inventory management interview questions, complete with explanations and sample answers to give you a leg up in your preparation.

Our aim is to provide you with a comprehensive toolkit that you can use to prepare for your inventory management interview. Whether you’re a seasoned pro or fresh out of college, these questions and answers will help you get into the right frame of mind and hopefully, land that job you’re gunning for.

- Top 19 Inventory Management Interview Questions and Answers

- 1. Can you explain what Inventory Management is?

- 2. What is the Importance of Inventory Turnover Ratio?

- 3. Can you list some types of Inventory?

- 4. How do you prioritize which items to order?

- 5. Explain the Just-In-Time Inventory System.

- 6. What is a safety stock, and why is it important?

- 7. What do you understand by ABC analysis?

- 8. How do you handle obsolete inventory?

- 9. How do you maintain accurate inventory records?

- 10. What metrics do you use to assess inventory health?

- 11. Describe your experience with Warehouse Management Systems (WMS).

- 12. What is FIFO, and why is it important?

- 13. How do you forecast demand?

- 14. Explain the economic order quantity (EOQ) model.

- 15. How do you manage relationships with suppliers?

- 16. What strategies do you employ for reducing holding costs?

- 17. How do you handle stock discrepancies?

- 18. What is dropshipping, and how does it differ from traditional inventory management?

- 19. How do you ensure team compliance with inventory processes?

- Conclusion

Top 19 Inventory Management Interview Questions and Answers

Before we dive into the questions, remember that the interviewer is not only assessing your technical knowledge but also your problem-solving abilities, communication skills, and cultural fit for the company. With that said, let’s get started.

1. Can you explain what Inventory Management is?

Inventory management is all about tracking and controlling stock levels to ensure that the right amount of products are available at the right time. It involves a range of tasks including ordering, storing, and utilizing inventory.

Sample Answer

“Inventory management is the process of ordering, storing, and utilizing a company’s inventory. This includes the management of raw materials, components, and finished products, as well as warehousing and processing such items. Effective inventory management ensures that a business has the right products in the right quantity for sale, at the right time.”

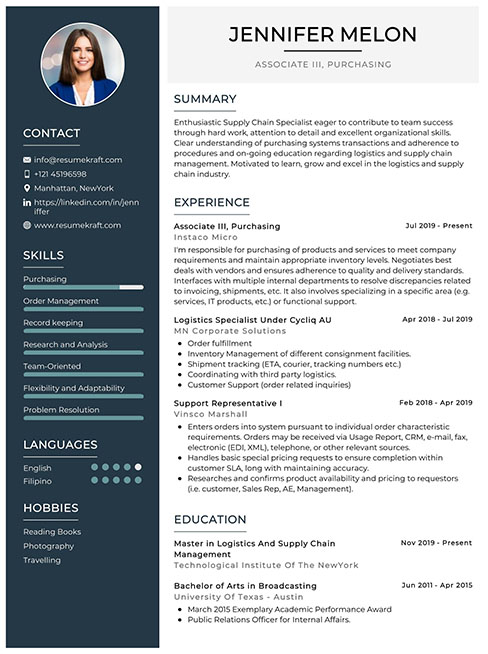

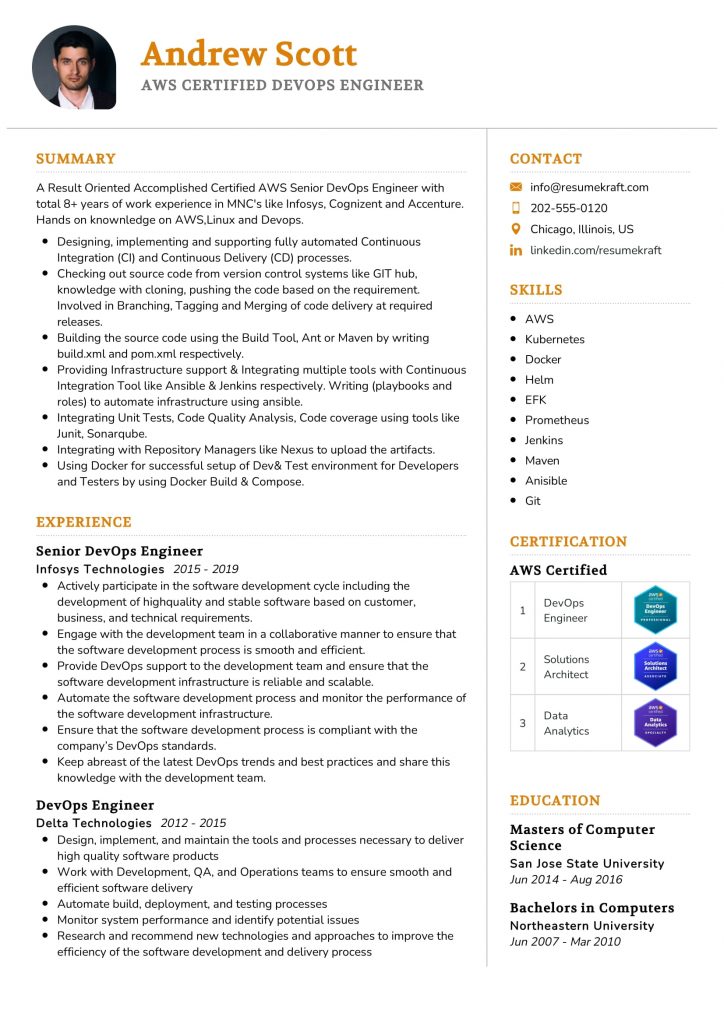

Build your resume in just 5 minutes with AI.

2. What is the Importance of Inventory Turnover Ratio?

The Inventory Turnover Ratio measures how many times a company’s inventory is sold and replaced over a specific period. It’s important because it provides insights into the efficiency of inventory management and sales performance.

Sample Answer

“The Inventory Turnover Ratio is crucial for understanding how efficiently a company is managing its inventory. A higher turnover ratio generally indicates that inventory is being sold quickly, suggesting strong sales and effective inventory management. Conversely, a lower turnover ratio may indicate overstocking, which ties up capital and increases holding costs.”

3. Can you list some types of Inventory?

Different types of inventory serve different purposes, from raw materials to work-in-progress to finished goods. Understanding these types is fundamental in inventory management.

Sample Answer

“Certainly, there are mainly three types of inventory: Raw Materials, Work-in-Progress, and Finished Goods. Raw Materials are the basic inputs in the manufacturing process. Work-in-Progress includes items that are currently being processed in the production line. Finally, Finished Goods are the completed products ready for sale.”

4. How do you prioritize which items to order?

Prioritizing items to order often depends on factors like demand, lead time, and holding costs. This question tests your strategic thinking.

Sample Answer

“To prioritize which items to order, I use a combination of factors. These include the item’s demand patterns, lead time for procurement, and the holding costs. Items with higher demand and longer lead times are generally prioritized, as running out of stock can lead to lost sales. The ABC analysis method can also be useful in this regard.”

5. Explain the Just-In-Time Inventory System.

Just-In-Time (JIT) is an inventory system that aims to minimize holding costs by ordering inventory only when needed. It’s a strategy that requires precision and strong supplier relationships.

Sample Answer

“The Just-In-Time (JIT) inventory system revolves around efficiency. The idea is to keep as little inventory as possible to minimize holding costs. You only order the materials you need when you need them, so you must have a very accurate forecasting system as well as reliable suppliers to avoid stock-outs.”

6. What is a safety stock, and why is it important?

Safety stock is essentially a buffer stock to guard against stockouts. It’s an insurance against variability in demand and lead time.

Sample Answer

“Safety stock is the extra inventory held to prevent stockouts. It’s a buffer that allows a business to meet unexpected spikes in demand or delays in supply. Having an appropriate level of safety stock is crucial for maintaining customer satisfaction and overall business continuity.”

7. What do you understand by ABC analysis?

ABC analysis is a popular inventory categorization technique. This question gauges your familiarity with inventory management techniques.

Sample Answer

“ABC analysis is an inventory categorization method that divides inventory into three categories based on their importance: ‘A’ being the most valuable items, ‘B’ being less valuable, and ‘C’ being the least valuable. This analysis helps in focusing resources where they’ll have the most impact, i.e., on high-value items.”

8. How do you handle obsolete inventory?

Obsolete inventory can be a financial drain, so it’s essential to deal with it effectively. This question probes your problem-solving skills.

Sample Answer

“Obsolete inventory should first be identified through regular audits. Once identified, multiple strategies can be employed

to deal with it, such as discount sales, bundling with other products, or even donating for a tax break. The key is to minimize the cost impact on the business.”

9. How do you maintain accurate inventory records?

Accurate inventory records are crucial for efficient operations and financial accounting. This tests your attention to detail.

Sample Answer

“Maintaining accurate inventory records involves a combination of methods such as regular physical audits, employing barcode scanning technology, and keeping an updated digital tracking system. The goal is to ensure that the digital records match the physical stock, making adjustments as needed.”

10. What metrics do you use to assess inventory health?

Metrics give insights into how well the inventory management system is working. This question tests your analytical skills.

Sample Answer

“To assess inventory health, I look at various metrics including Inventory Turnover Ratio, Days to Sell Inventory, Gross Margin Return on Investment, and Stock-to-Sales ratios. These metrics provide a comprehensive picture of how efficiently the inventory is being managed and where improvements can be made.”

11. Describe your experience with Warehouse Management Systems (WMS).

Warehouse Management Systems (WMS) are instrumental in optimizing various aspects of warehousing and inventory management. This question tests your technological proficiency.

Sample Answer

“I have hands-on experience with several Warehouse Management Systems like SAP WM, Oracle WMS, and Fishbowl. These systems are essential for real-time inventory tracking, optimizing storage space, and facilitating seamless picking and packing operations. They significantly improve operational efficiency and data accuracy.”

12. What is FIFO, and why is it important?

First-In, First-Out (FIFO) is an inventory valuation method where the oldest inventory items are sold first. Understanding FIFO is essential for effective stock rotation.

Sample Answer

“FIFO stands for First-In, First-Out, a method used to ensure that the oldest inventory is sold before the newer inventory. This is particularly important for perishable goods, as it helps to minimize waste. It’s also beneficial for non-perishable items to prevent them from becoming obsolete.”

13. How do you forecast demand?

Demand forecasting is at the heart of inventory management. This question gauges your analytical and strategic planning skills.

Sample Answer

“I usually rely on a combination of qualitative and quantitative methods for demand forecasting. Historical sales data, market trends, and seasonality are considered. I also incorporate feedback from the sales and marketing teams. Advanced statistical tools and software can help make the forecast more accurate.”

14. Explain the economic order quantity (EOQ) model.

The Economic Order Quantity (EOQ) model is a classic inventory management tool that minimizes total holding and order costs.

Sample Answer

“The Economic Order Quantity (EOQ) model is used to determine the optimal order quantity that minimizes the total inventory costs, which include holding costs and order costs. The model helps in deciding the best quantity to order so that you have enough stock until the next order but not so much that you’re incurring high holding costs.”

15. How do you manage relationships with suppliers?

Managing supplier relationships is critical for inventory management, especially when following models like Just-In-Time.

Sample Answer

“Building strong relationships with suppliers is crucial for timely and reliable inventory supply. I focus on open communication, fair negotiation, and long-term partnership-building. Regular meetings, performance reviews, and adherence to agreements build trust and ensure a reliable supply chain.”

16. What strategies do you employ for reducing holding costs?

Reducing holding costs directly impacts profitability. Your answer should reflect your capability to implement cost-saving measures.

Sample Answer

“To reduce holding costs, I focus on optimizing warehouse layout for efficient space utilization and employing a real-time tracking system to minimize retrieval time. Additionally, implementing inventory models like JIT can reduce the amount of stock held, thereby lowering holding costs.”

17. How do you handle stock discrepancies?

Discrepancies in stock levels can lead to various operational issues. This tests your problem-solving and crisis management skills.

Sample Answer

“When discrepancies arise, I first conduct a thorough stock audit to identify the source of the problem. Then, I analyze the situation to determine if the discrepancy is a one-time error or if there is a systematic issue. Solutions may involve retraining staff, updating systems, or even redesigning processes.”

18. What is dropshipping, and how does it differ from traditional inventory management?

Dropshipping is a retail fulfillment model where a store doesn’t keep products in stock. Understanding different models shows your versatility in the field.

Sample Answer

“Dropshipping is a model where the store doesn’t hold the products it sells. Instead, when an order is placed, the item is purchased from a third-party supplier who ships it directly to the customer. This differs from traditional inventory management where products are purchased in bulk and stored until sold.”

19. How do you ensure team compliance with inventory processes?

Ensuring compliance is critical for maintaining accurate and efficient operations. This question tests your leadership and managerial skills.

Sample Answer

“Ensuring compliance starts with proper training and clear documentation of inventory processes. Regular audits and reviews provide accountability. Additionally, using advanced WMS systems can automate many compliance tasks, making it easier for the team to adhere to best practices.”

Conclusion

There you have it—the top 19 inventory management interview questions you’re likely to face, along with well-crafted sample answers to help you prepare. Whether you’re a fresh graduate or an experienced professional, having comprehensive answers to these questions will place you several steps ahead in the interview process. Good luck!

Remember to utilize resources like AI Resume Builder, Resume Design, Resume Samples, Resume Examples, Resume Skills, Resume Help, Resume Synonyms, and Job Responsibilities to create a standout application and prepare for the interview.

Build your resume in 5 minutes

Our resume builder is easy to use and will help you create a resume that is ATS-friendly and will stand out from the crowd.