Preparing for a Packaging Development Supervisor interview is crucial, as this role combines creativity with technical expertise in the packaging industry. As a Packaging Development Supervisor, you’ll be responsible for overseeing the design and implementation of packaging solutions that not only protect products but also enhance consumer appeal and sustainability. Proper interview preparation can set you apart, showcasing your knowledge of materials, processes, and industry trends. This comprehensive guide will cover common interview questions, key competencies for the role, and strategies to effectively communicate your experience and vision, ensuring you present yourself as the ideal candidate for this unique and impactful position.

- What to Expect in a Packaging Development Supervisor Interview

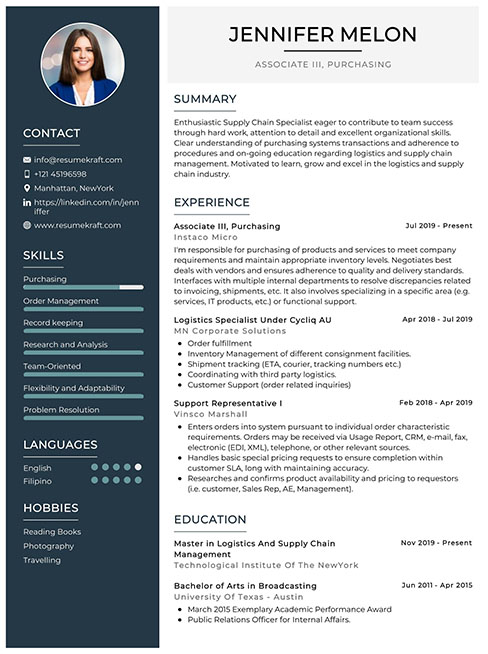

- Packaging Development Supervisor Interview Questions For Freshers

- Packaging Development Supervisor Intermediate Interview Questions

- Packaging Development Supervisor Interview Questions for Experienced

- How to Prepare for Your Packaging Development Supervisor Interview

What to Expect in a Packaging Development Supervisor Interview

In a Packaging Development Supervisor interview, candidates can expect a mix of technical and behavioral questions aimed at evaluating their expertise in packaging processes and team management. Interviews may be conducted by a panel including hiring managers, senior engineers, and HR representatives. The structure typically begins with an introduction, followed by questions related to previous experience, technical skills in packaging materials and design, and situational scenarios to assess problem-solving abilities. Candidates may also be asked to present case studies or previous projects to demonstrate their skills and experience in packaging development.

Packaging Development Supervisor Interview Questions For Freshers

This set of interview questions is tailored for freshers aspiring to become Packaging Development Supervisors. It covers fundamental concepts such as materials, design processes, sustainability, and regulatory compliance that candidates should master to succeed in this role.

1. What is the role of a Packaging Development Supervisor?

A Packaging Development Supervisor oversees the design and development of packaging materials and processes. They are responsible for ensuring that packaging meets product requirements, is cost-effective, and complies with regulations. Additionally, they coordinate with various teams, manage projects, and ensure that packaging solutions enhance product protection and consumer appeal.

2. What are some common materials used in packaging?

- Paperboard: Lightweight and recyclable, often used for boxes and cartons.

- Plastic: Versatile and durable, used for bottles, films, and containers.

- Glass: Provides a premium feel and is inert, making it suitable for food and beverages.

- Metal: Commonly used in cans, it offers excellent protection against light and oxygen.

Understanding these materials helps in selecting the right option based on product needs and sustainability considerations.

3. What factors should be considered when designing packaging?

- Product Protection: Ensuring the packaging protects the product during transit and storage.

- Cost Efficiency: Balancing quality with the cost of materials and production.

- Consumer Appeal: Designing packaging that attracts consumers and communicates brand identity.

- Regulatory Compliance: Following legal requirements regarding labeling and materials.

These factors are crucial for effective packaging that meets both business and customer needs.

Build your resume in just 5 minutes with AI.

4. What is sustainable packaging?

Sustainable packaging refers to packaging solutions that minimize environmental impact. This can include using recyclable materials, reducing packaging size, and employing biodegradable options. The goal is to create packaging that meets consumer needs while being environmentally friendly, thus supporting corporate responsibility and sustainability initiatives.

5. How do you determine the right size for packaging?

Determining the right size for packaging involves considering the dimensions of the product, including its shape and weight. Additionally, factors such as shipping efficiency, storage capabilities, and protection during transportation must be evaluated. Using design software can aid in visualizing and optimizing packaging dimensions for various needs.

6. What is the importance of labeling in packaging?

Labeling is critical as it provides essential information to consumers, including product contents, usage instructions, and safety warnings. It also includes branding elements that help differentiate products in the marketplace. Proper labeling ensures compliance with regulations and enhances the overall consumer experience.

7. Can you explain the term ‘packaging life cycle’?

The packaging life cycle encompasses all stages from material sourcing to disposal. It includes design, production, transportation, usage, and end-of-life options like recycling or landfill. Understanding the life cycle helps assess the environmental impact of packaging and identify opportunities for improvement in sustainability practices.

8. What role does technology play in packaging development?

Technology enhances packaging development through innovations such as automated design software, 3D modeling, and testing tools. It allows for more efficient design processes, better performance testing, and improved materials research. Technology also supports the implementation of smart packaging solutions that can engage consumers and provide additional product information.

9. How do you ensure quality control in packaging?

- Regular Testing: Conducting strength, durability, and safety tests on packaging materials.

- Supplier Audits: Ensuring that material suppliers meet quality standards and specifications.

- Feedback Loops: Gathering input from production and logistics teams to identify issues.

Implementing these practices establishes a robust quality control system that minimizes defects and enhances overall packaging performance.

10. What are some common challenges in packaging development?

- Cost Management: Balancing quality with production costs can be challenging.

- Regulatory Compliance: Staying updated with changing packaging regulations can be complex.

- Consumer Trends: Adapting packaging to meet evolving consumer preferences requires flexibility.

Addressing these challenges requires proactive planning and continuous market research.

11. What is the role of prototyping in packaging design?

Prototyping allows designers to create physical representations of packaging concepts. This process helps in evaluating design effectiveness, testing materials, and identifying potential issues before mass production. Prototypes can be used for consumer testing, providing valuable insights into customer preferences and usability.

12. How do you approach cost reduction in packaging?

- Material Optimization: Choosing cost-effective yet durable materials.

- Design Efficiency: Streamlining designs to reduce material waste.

- Supplier Negotiations: Building relationships with suppliers to negotiate better pricing.

These strategies can significantly lower packaging costs while maintaining quality and functionality.

13. What software tools are commonly used in packaging design?

- Adobe Illustrator: For graphic design and label creation.

- ArtiosCAD: For structural design and 3D modeling of packaging.

- SolidWorks: For engineering and testing packaging designs.

Familiarity with these tools enhances a designer’s ability to create effective packaging solutions efficiently.

14. Why is consumer feedback important in packaging development?

Consumer feedback provides insights into how packaging performs in real-world conditions. It helps identify strengths and weaknesses, guiding future design improvements. Understanding consumer preferences also ensures that packaging meets market expectations, enhancing brand loyalty and product sales.

15. What steps would you take to improve an existing packaging design?

- Conduct a Review: Analyze current designs for functionality, cost, and consumer feedback.

- Research Trends: Stay updated on industry trends and technological advancements.

- Test New Concepts: Create prototypes and conduct consumer tests to gather insights.

Improving packaging design requires a systematic approach that balances innovation with practical considerations.

Here are four interview questions designed for freshers applying for a Packaging Development Supervisor position. These questions focus on fundamental concepts relevant to the role.

16. What is the role of a Packaging Development Supervisor?

A Packaging Development Supervisor is responsible for overseeing the design, development, and optimization of packaging solutions. This role includes coordinating with cross-functional teams to ensure packaging meets regulatory standards, production efficiency, and sustainability goals. They also manage projects from concept to implementation while ensuring that packaging aligns with brand strategy and consumer needs.

17. What are the key factors to consider when developing packaging?

- Material Selection: Choose materials that provide protection while being cost-effective and sustainable.

- Design and Branding: Ensure the packaging design aligns with brand identity and attracts consumers.

- Regulatory Compliance: Adhere to industry regulations regarding safety, labeling, and environmental impact.

- Functionality: Packaging should be easy to open, reseal, and use while maintaining product integrity.

Considering these factors helps create effective packaging that meets both business and consumer needs.

18. Can you explain the importance of sustainability in packaging development?

Sustainability in packaging development is crucial due to growing consumer awareness and regulatory pressures. Sustainable packaging reduces environmental impact by minimizing waste and using recyclable or biodegradable materials. It enhances brand image and customer loyalty, as consumers increasingly prefer products that are eco-friendly. Furthermore, adopting sustainable practices can lead to cost savings and improved efficiency in the supply chain.

19. What tools or software are commonly used in packaging design?

- Adobe Illustrator: Widely used for creating packaging graphics and layouts.

- ArtiosCAD: A specialized software for designing packaging structures and prototypes.

- SolidWorks: Used for 3D modeling of packaging to visualize and test designs.

- PACKZ: A tool for prepress and packaging workflows to ensure print quality.

Familiarity with these tools is essential for effective packaging development and design processes.

Packaging Development Supervisor Intermediate Interview Questions

This set of interview questions is tailored for candidates applying for a Packaging Development Supervisor role at an intermediate level. Candidates should be familiar with packaging materials, design processes, project management, and compliance standards to effectively lead packaging development projects.

20. What are the key factors to consider when selecting packaging materials?

When selecting packaging materials, consider the following key factors:

- Product Protection: Ensure the material protects the product from physical damage, moisture, and light.

- Cost Efficiency: Assess the material’s cost relative to the budget while maintaining quality.

- Environmental Impact: Opt for sustainable materials that minimize ecological footprint.

- Regulatory Compliance: Ensure materials meet safety and regulatory standards for the specific industry.

- Branding: Choose materials that align with the brand image and marketing strategy.

These factors collectively contribute to the effectiveness and sustainability of packaging solutions.

21. How do you approach the design process for a new packaging concept?

The design process for a new packaging concept involves several steps:

- Research: Understand the product requirements, target market, and competitor packaging.

- Brainstorming: Generate ideas and potential designs considering functionality and aesthetics.

- Prototyping: Create prototypes to evaluate design and functionality.

- Testing: Conduct tests for durability, usability, and consumer feedback.

- Finalization: Refine the design based on feedback and prepare for production.

This structured approach ensures that the final packaging meets both functional and market needs.

22. What testing methods do you recommend for packaging materials?

Recommended testing methods for packaging materials include:

- Compression Testing: Assess the material’s ability to withstand weight and pressure.

- Drop Testing: Evaluate how materials perform when dropped from various heights.

- Environmental Testing: Simulate conditions like humidity and temperature to test durability.

- Seal Integrity Testing: Check the effectiveness of seals in preventing leaks and contamination.

- Consumer Testing: Collect feedback from potential customers on usability and appeal.

These tests help ensure that packaging materials are reliable and suitable for their intended use.

23. Can you explain the importance of sustainability in packaging development?

Sustainability in packaging development is crucial as it addresses environmental concerns and consumer preferences. It helps reduce waste, lower carbon footprints, and comply with regulations. Sustainable packaging can enhance a brand’s image, attract eco-conscious consumers, and contribute to long-term cost savings through the use of recyclable or biodegradable materials. A focus on sustainability can also foster innovation and open new market opportunities.

24. How do you manage timelines and budgets during a packaging project?

Managing timelines and budgets during a packaging project involves:

- Setting Clear Milestones: Define specific objectives and deliverables to track progress.

- Resource Allocation: Assign tasks based on team strengths and availability.

- Regular Monitoring: Use project management tools to monitor progress and adjust as needed.

- Stakeholder Communication: Keep stakeholders informed about changes to timelines or budgets.

- Risk Assessment: Identify potential risks early and develop mitigation strategies.

These practices help ensure projects are completed on time and within budget.

25. What are some common challenges faced in packaging development?

Common challenges in packaging development include:

- Material Limitations: Finding materials that meet both performance and sustainability requirements can be difficult.

- Cost Constraints: Balancing quality with budget limitations often presents challenges.

- Regulatory Compliance: Staying updated with packaging regulations across different regions can be complex.

- Market Trends: Adapting to rapidly changing consumer preferences requires ongoing research.

- Supply Chain Issues: Disruptions in the supply chain can delay production and impact costs.

Addressing these challenges requires proactive planning and adaptability.

26. Describe your experience with project management software in packaging development.

Project management software plays a vital role in packaging development by facilitating collaboration, tracking progress, and managing resources. Tools like Trello, Asana, or Microsoft Project allow teams to create timelines, assign tasks, and monitor deadlines. These systems help identify bottlenecks, ensure accountability, and improve overall project communication, thereby enhancing efficiency and effectiveness in packaging projects.

27. How do you ensure quality control in packaging production?

Ensuring quality control in packaging production involves:

- Standard Operating Procedures (SOPs): Develop and implement SOPs for production processes.

- Regular Inspections: Conduct routine checks throughout the production process to identify defects.

- Testing Protocols: Establish testing protocols to verify material integrity and compliance.

- Feedback Loops: Create channels for feedback from production staff and customers to address concerns.

- Continuous Improvement: Use data from quality checks to refine processes and reduce errors.

This comprehensive approach helps maintain high standards of quality in packaging production.

28. What role does consumer feedback play in packaging design?

Consumer feedback is crucial in packaging design as it provides insights into preferences, usability, and appeal. Gathering feedback through surveys, focus groups, or testing can highlight areas for improvement and validate design choices. Incorporating consumer insights ensures that packaging resonates with the target audience, enhances user experience, and ultimately drives sales. It fosters a customer-centric approach in the design process.

29. Explain how you would approach a redesign of existing packaging.

Approaching a redesign of existing packaging involves several steps:

- Assessment: Analyze the current packaging to identify weaknesses and areas for improvement.

- Research: Gather consumer insights and market trends to inform design decisions.

- Concept Development: Create new design concepts that address identified issues while enhancing aesthetics.

- Prototyping and Testing: Develop prototypes and conduct testing to evaluate the new design’s effectiveness.

- Implementation: Finalize the design and plan for a smooth transition to production.

This systematic approach ensures that the redesign meets both functional and market needs.

30. What factors do you consider when designing for different distribution channels?

When designing for different distribution channels, consider:

- Protection Requirements: Different channels may expose products to varying risks, necessitating different protective features.

- Size and Weight: Optimize packaging to reduce shipping costs while ensuring product safety.

- Brand Visibility: Design packaging that is eye-catching and aligns with marketing strategies for each channel.

- Compliance: Ensure packaging meets the regulations of each distribution channel.

- Consumer Interaction: Tailor the packaging design for the end-user experience, depending on the channel.

These factors help ensure that packaging is effective and practical across various distribution methods.

31. Describe a situation where you had to deal with a packaging failure. What did you learn?

In a previous role, we experienced a packaging failure due to a design flaw that led to product damage during transit. We conducted a root cause analysis which revealed deficiencies in our testing protocols. I learned the importance of rigorous testing and the need for detailed documentation throughout the design process. This incident prompted us to enhance our quality control measures and develop more robust testing protocols to prevent similar issues in the future.

32. How do you stay updated on packaging trends and technology?

To stay updated on packaging trends and technology, I engage in various activities, such as:

- Industry Conferences: Attend conferences and trade shows to learn about the latest innovations and network with professionals.

- Trade Publications: Subscribe to packaging industry journals and newsletters for insights on emerging trends.

- Online Courses: Participate in webinars and online courses to expand my knowledge of new technologies.

- Professional Associations: Join organizations like the Institute of Packaging Professionals to access resources and networking opportunities.

- Peer Networking: Regularly connect with colleagues and industry experts to share insights and experiences.

These activities help me remain informed and competitive in the evolving packaging landscape.

Here are some intermediate-level interview questions for the position of Packaging Development Supervisor, focusing on practical applications and best practices in the field.

35. What are the key considerations when developing packaging for a new product?

When developing packaging for a new product, consider the following key aspects:

- Material Selection: Choose materials that protect the product, are sustainable, and align with brand values.

- Cost Efficiency: Analyze production costs, shipping expenses, and material availability to ensure the packaging is economically viable.

- Consumer Appeal: Design packaging that attracts consumers and communicates the product’s benefits effectively.

- Regulatory Compliance: Ensure that packaging meets all industry regulations and safety standards.

- Functionality: The packaging should facilitate ease of use, storage, and transportation.

These considerations help ensure that the packaging meets market demands while also supporting sustainability and cost-effectiveness.

36. How do you evaluate the sustainability of packaging materials?

Evaluating the sustainability of packaging materials involves several steps:

- Life Cycle Assessment (LCA): Conduct an LCA to analyze the environmental impact of materials from production to disposal.

- Material Sourcing: Assess the sourcing of materials, ensuring they are renewable or recycled and free from harmful chemicals.

- End-of-Life Options: Consider how the packaging can be recycled, composted, or reused after its initial use.

- Carbon Footprint: Measure the carbon emissions associated with the material’s production and transportation.

By focusing on these areas, you can make informed decisions that promote sustainability in packaging development.

37. What steps would you take to improve the efficiency of the packaging process?

To improve the efficiency of the packaging process, consider implementing the following strategies:

- Automation: Invest in automated packaging machinery to reduce labor costs and increase speed.

- Process Optimization: Analyze current workflows to identify bottlenecks and streamline operations.

- Employee Training: Provide training to staff on best practices and the efficient use of packaging equipment.

- Material Utilization: Optimize material usage to minimize waste and reduce costs.

- Feedback Loops: Establish regular feedback from the production team to continuously improve processes based on real-world experiences.

By focusing on these areas, you can enhance efficiency, reduce costs, and improve overall productivity in the packaging process.

38. Can you describe a time when you had to handle a packaging design failure? What steps did you take?

In a previous role, we faced a packaging design failure where the primary packaging could not withstand shipping conditions, leading to product damage. The steps I took included:

- Root Cause Analysis: Conducted a thorough analysis to identify the specific failure points in the design and materials used.

- Cross-Functional Collaboration: Worked closely with the design, engineering, and quality assurance teams to brainstorm solutions.

- Prototyping: Developed new prototypes using more robust materials and tested them under real shipping conditions.

- Consumer Feedback: Gathered feedback from consumers on the new design to ensure it met their expectations.

- Implementation: Rolled out the improved packaging design and monitored its performance in the market.

This experience reinforced the importance of testing and collaboration in packaging development to avoid future failures.

Packaging Development Supervisor Interview Questions for Experienced

This set of interview questions is tailored for experienced professionals applying for the role of Packaging Development Supervisor. The questions focus on advanced topics such as architectural design, optimization techniques, scalability challenges, design patterns, and leadership qualities necessary for mentoring teams in the packaging development field.

39. What are the key architectural considerations for packaging design?

Key architectural considerations for packaging design include material selection, structural integrity, product protection, sustainability, and manufacturability. It’s crucial to ensure that the packaging meets regulatory requirements while also being cost-effective. Additionally, the design should facilitate efficient logistics and supply chain management, optimizing space during storage and transportation.

40. How do you approach optimizing packaging for sustainability?

- Material Reduction: Choose materials that minimize waste without compromising quality.

- Recyclability: Select materials that are easily recyclable or made from recycled content.

- Energy Efficiency: Evaluate manufacturing processes to reduce energy consumption.

- Life Cycle Assessment: Conduct assessments to understand the environmental impact throughout the packaging lifecycle.

By addressing these points, you can create packaging solutions that are not only functional but also environmentally friendly.

41. Can you explain a design pattern you’ve implemented in packaging development?

One effective design pattern in packaging development is the Factory Pattern. This pattern allows for the creation of packaging objects without specifying the exact class of object that will be created. This is useful for managing different packaging types based on product requirements. For example:

public interface Packaging {

void pack();

}

public class Box implements Packaging {

public void pack() {

System.out.println("Packing in a box.");

}

}

public class Bag implements Packaging {

public void pack() {

System.out.println("Packing in a bag.");

}

}

public class PackagingFactory {

public static Packaging getPackaging(String type) {

if (type.equals("box")) {

return new Box();

} else if (type.equals("bag")) {

return new Bag();

}

return null;

}

}This pattern enhances scalability and flexibility in the packaging line.

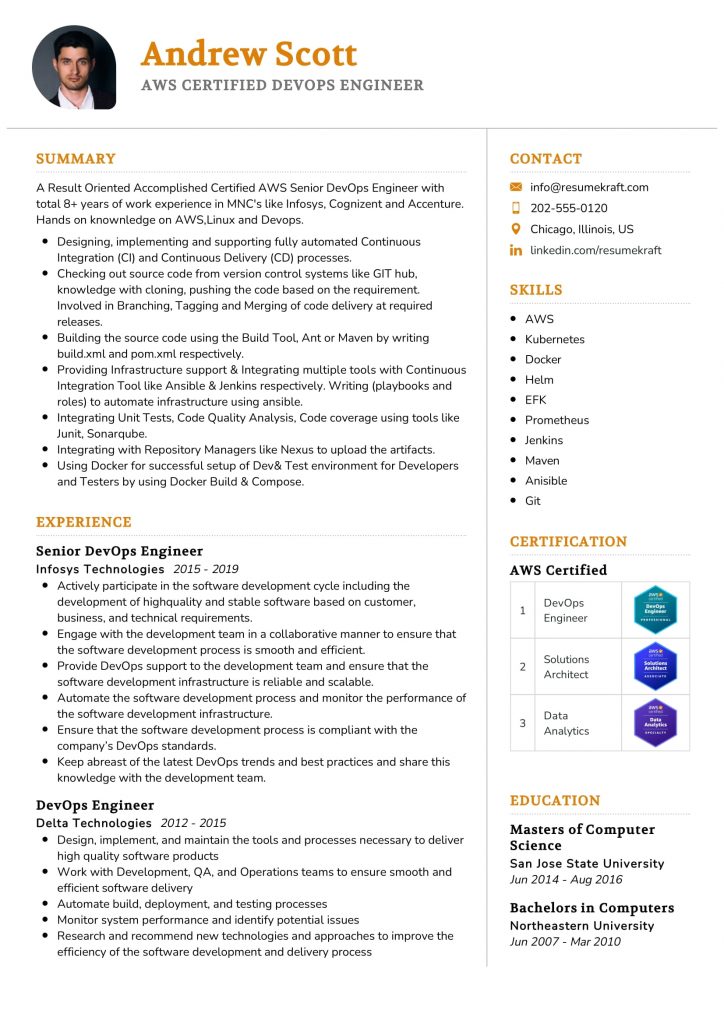

Build your resume in 5 minutes

Our resume builder is easy to use and will help you create a resume that is ATS-friendly and will stand out from the crowd.

42. How do you ensure packaging designs are scalable for mass production?

To ensure scalability, it’s essential to collaborate closely with manufacturing teams early in the design process. Key strategies include:

- Prototyping: Create prototypes to test the design in a production environment.

- Standardization: Use standardized materials and components to streamline production.

- Automation: Design for automation to reduce labor costs and increase efficiency.

- Feedback Loops: Implement feedback mechanisms from production staff to continuously improve designs.

These steps help in aligning packaging design with production capabilities.

43. What role does leadership play in a packaging development team?

Leadership in a packaging development team is crucial for fostering collaboration, guiding project vision, and mentoring team members. Strong leaders set clear objectives, facilitate communication, and encourage innovative thinking. They also help navigate challenges by leveraging team strengths and ensuring that deadlines are met. Effective leadership builds a positive team culture that drives success.

44. Describe a time you had to mentor a junior team member in packaging development.

In my previous role, I mentored a junior designer who struggled with material selection. I organized regular one-on-one sessions to discuss the properties of different materials and how they impact packaging performance. By providing resources and encouraging hands-on learning through projects, I helped them gain confidence. This ultimately improved their design decisions and contributed to successful project outcomes.

45. How do you handle conflicts within your packaging development team?

Handling conflicts requires open communication and a focus on problem-solving. I encourage team members to express their concerns and perspectives in a constructive manner. Facilitating a collaborative discussion often reveals underlying issues that can be addressed. If necessary, I involve a neutral third party to mediate. The goal is to reach a consensus that prioritizes the project’s success.

46. What metrics do you use to evaluate packaging performance?

- Cost Efficiency: Analyze production and material costs against budget.

- Durability: Test packaging for resistance to damage during transit.

- Consumer Feedback: Gather insights on usability and appeal.

- Sustainability: Measure environmental impact through life cycle assessments.

These metrics provide a well-rounded view of packaging performance and guide improvements.

47. How do you keep up with industry trends in packaging development?

I stay current by engaging with industry publications, attending relevant conferences, and participating in professional networks. Online courses and webinars also provide insights into emerging technologies and sustainability practices. By actively seeking knowledge and sharing it with my team, I help ensure our packaging strategies remain competitive and innovative.

48. Describe a project where you implemented a new packaging technology.

In a recent project, I led the implementation of a new digital printing technology for packaging labels. This allowed for greater customization and reduced lead times. We conducted a pilot project to assess quality and efficiency, which led to a full rollout. The new technology improved our market responsiveness and reduced costs associated with traditional printing methods.

49. What are the challenges of international packaging regulations?

International packaging regulations can vary significantly, posing challenges such as compliance with local laws, tariffs, and environmental standards. It’s essential to conduct thorough research on each market’s requirements. Adapting designs to meet these regulations can lead to increased costs and longer lead times. Maintaining flexibility and a robust compliance strategy is crucial for successful international operations.

50. How do you prioritize packaging design projects?

- Market Demand: Assess the urgency based on consumer needs and sales forecasts.

- Strategic Goals: Align projects with the company’s long-term objectives.

- Resource Availability: Consider team capacity and resource constraints.

- Risk Assessment: Evaluate potential risks and impacts on brand reputation.

By weighing these criteria, I can prioritize projects effectively to maximize impact and efficiency.

51. How do you manage vendor relationships in packaging development?

Managing vendor relationships involves clear communication, setting expectations, and fostering collaboration. I regularly meet with vendors to discuss performance metrics, address issues, and explore opportunities for innovation. Building strong partnerships based on trust and mutual benefit leads to better pricing, quality materials, and improved lead times, ultimately enhancing our packaging development process.

Here are some interview questions tailored for a Packaging Development Supervisor position. These questions focus on architecture, optimization, scalability, design patterns, and leadership/mentoring aspects relevant to the role.

54. What are the key considerations when designing packaging for a new product?

When designing packaging for a new product, key considerations include:

- Functionality: The packaging must protect the product during transit and storage while being easy to open for consumers.

- Materials: Choosing sustainable materials that comply with regulations and minimize environmental impact is crucial.

- Branding: The packaging should reflect the brand’s identity and values, making it visually appealing to attract consumers.

- Cost: Balancing quality and cost-effectiveness is essential to maintain profitability.

- Compliance: Ensuring that packaging meets industry standards and regulations is critical to avoid legal issues.

These considerations help in creating packaging that not only protects the product but also enhances customer experience and brand recognition.

55. How do you approach optimizing packaging design for cost and sustainability?

To optimize packaging design for cost and sustainability, I adopt the following strategies:

- Material Reduction: Analyze the packaging design to eliminate unnecessary materials without compromising protection and usability.

- Eco-Friendly Materials: Source recyclable or biodegradable materials that align with sustainability goals.

- Design for Efficiency: Create designs that maximize space during shipping and storage, reducing transportation costs and carbon footprint.

- Supplier Collaboration: Work closely with suppliers to identify innovative materials and processes that lower costs while enhancing sustainability.

These strategies not only lead to cost savings but also contribute to the company’s environmental responsibility initiatives.

56. Can you describe a design pattern that is particularly effective in packaging development?

A widely used design pattern in packaging development is the Modular Packaging Pattern. This involves creating packaging components that can be easily combined or rearranged to accommodate different product sizes or configurations. Key benefits include:

- Flexibility: Modular designs allow for quick adjustments to packaging for varying product lines without redesigning the entire system.

- Cost Efficiency: Reducing the number of different packaging types lowers inventory costs and simplifies logistics.

- Scalability: As product lines expand, modular packaging can be scaled up quickly to meet new demands.

This pattern supports efficient production and distribution processes, making it a valuable approach in packaging development.

57. How do you mentor and lead a team in packaging development?

Mentoring and leading a team in packaging development involves several key strategies:

- Setting Clear Goals: Establish clear, achievable objectives for the team to align their efforts and measure progress.

- Encouraging Collaboration: Foster a collaborative environment where team members feel comfortable sharing ideas and feedback.

- Providing Training: Offer training sessions on the latest packaging technologies and trends to keep the team updated and engaged.

- Recognizing Achievements: Acknowledge individual and team successes to motivate and build morale.

- Continuous Improvement: Promote a culture of continuous improvement by encouraging team members to suggest enhancements to processes and designs.

Effective mentoring not only enhances team performance but also contributes to personal growth and job satisfaction among team members.

58. What tools and technologies do you find essential for packaging development?

Essential tools and technologies for packaging development include:

- CAD Software: Tools like AutoCAD or SolidWorks help in designing and visualizing packaging structures efficiently.

- 3D Printing: Useful for creating prototypes quickly, allowing for better visualization and testing of packaging designs.

- Simulation Software: Programs that simulate the packaging performance during transportation and handling, helping identify potential issues before production.

- Sustainability Assessment Tools: Tools that help evaluate the environmental impact of packaging materials and designs, ensuring compliance with sustainability goals.

Utilizing these technologies enhances the efficiency and effectiveness of the packaging development process.

How to Prepare for Your Packaging Development Supervisor Interview

Preparing for a Packaging Development Supervisor interview requires a thorough understanding of packaging processes, materials, and team management. Focusing on industry-specific knowledge and demonstrating leadership skills will enhance your chances of making a positive impression during the interview.

- Understand Packaging Materials: Research different types of packaging materials, their properties, and applications. Familiarize yourself with sustainable packaging options, as companies increasingly prioritize eco-friendly solutions. Be ready to discuss how you can implement these materials in product development.

- Review Industry Trends: Stay informed about the latest trends in packaging technology, design, and regulations. Understanding advancements like smart packaging or automation can set you apart. Use this knowledge to discuss how you can contribute to innovative packaging solutions.

- Brush Up on Regulations: Familiarize yourself with industry regulations and standards, such as FDA guidelines or ISO certifications relevant to packaging. Be prepared to explain how you ensure compliance in packaging development and quality assurance processes.

- Highlight Leadership Skills: As a supervisor, showcasing your leadership abilities is crucial. Prepare examples of how you’ve successfully led teams, resolved conflicts, and motivated team members. Emphasize your communication and project management skills during the interview.

- Practice Problem-Solving Scenarios: Anticipate questions about common packaging challenges, such as cost reduction or improving sustainability. Prepare structured responses outlining your approach to problem-solving, including identifying issues, brainstorming solutions, and implementing changes effectively.

- Prepare Your Portfolio: If applicable, compile a portfolio of past packaging projects that showcase your skills and achievements. Include visuals, metrics, and testimonials to demonstrate your impact on previous employers and your ability to drive packaging innovation.

- Conduct Mock Interviews: Practice with a friend or mentor who can simulate the interview environment. Focus on articulating your experiences clearly and confidently. Seek feedback on your responses and body language to refine your presentation skills before the actual interview.

Common Packaging Development Supervisor Interview Mistakes to Avoid

When interviewing for a Packaging Development Supervisor position, candidates should be aware of common pitfalls that can hinder their chances of success. Understanding these mistakes can help you present yourself more effectively and align your skills with the employer’s needs.

- Neglecting Industry Knowledge: Failing to research the packaging industry trends can result in uninformed answers. A solid understanding of current materials, sustainability practices, and regulatory standards is crucial for success in this role.

- Overlooking Technical Skills: Packaging development requires specific technical skills, such as proficiency in CAD software and familiarity with packaging materials. Candidates should be prepared to discuss their technical expertise and provide examples of relevant projects.

- Inadequate Problem-Solving Examples: Employers seek candidates who can navigate challenges. Not providing concrete examples of previous problem-solving experiences in packaging development can make you seem less capable or unprepared.

- Ignoring Team Collaboration: Packaging development is often a collaborative effort. Failing to highlight your experience working with cross-functional teams can give the impression that you might struggle in a team-oriented environment.

- Not Asking Questions: Candidates who don’t ask insightful questions may appear disinterested. Prepare thoughtful questions about the company’s packaging strategies or team dynamics to demonstrate your enthusiasm for the role.

- Being Unprepared for Behavioral Questions: Packaging development supervisors must demonstrate leadership and decision-making skills. Not preparing for behavioral interview questions can lead to vague responses that fail to showcase your qualifications.

- Underestimating the Importance of Sustainability: With a growing emphasis on eco-friendly packaging, candidates must be ready to discuss sustainable practices. Failing to address this topic can suggest a lack of awareness of industry shifts.

- Poor Communication Skills: As a supervisor, effective communication is essential. Failing to articulate your thoughts clearly during the interview can raise concerns about your ability to lead and manage teams effectively.

Key Takeaways for Packaging Development Supervisor Interview Success

- Prepare your resume using an AI resume builder to ensure it’s tailored to the Packaging Development Supervisor role, highlighting relevant skills and achievements effectively.

- Use appropriate resume templates to maintain a professional format, ensuring clarity and easy navigation for hiring managers reviewing your application.

- Showcase your experience with strong resume examples that align with the job description, demonstrating how your background meets the needs of the packaging development team.

- Craft compelling cover letters that personalize your application, explaining why you are the ideal candidate for the Packaging Development Supervisor position and your passion for the industry.

- Engage in mock interview practice to build confidence and refine your responses, focusing on common questions and scenarios specific to packaging development and supervisory roles.

Frequently Asked Questions

1. How long does a typical Packaging Development Supervisor interview last?

A typical interview for a Packaging Development Supervisor position lasts between 45 minutes to an hour. This timeframe allows interviewers to assess your technical knowledge, project management skills, and experience in packaging development. Expect questions that cover both your hard skills, such as familiarity with materials and design processes, and soft skills, like teamwork and communication. Be prepared to discuss your past projects and how they relate to the company’s needs.

2. What should I wear to a Packaging Development Supervisor interview?

For a Packaging Development Supervisor interview, it’s best to dress in business professional attire. This typically includes a tailored suit or blazer, dress shirt, and dress shoes. Opt for neutral colors to convey professionalism and confidence. If the company has a more casual culture, business casual may be acceptable, but when in doubt, it’s better to err on the side of formality. Your appearance should reflect your seriousness about the role.

3. How many rounds of interviews are typical for a Packaging Development Supervisor position?

Typically, the interview process for a Packaging Development Supervisor position may consist of two to three rounds. The first round is often a phone or video interview focusing on your background and technical skills. Subsequent rounds may include in-person interviews with hiring managers or team members, assessing cultural fit, leadership qualities, and problem-solving abilities. Some companies may also require a presentation or case study to evaluate your practical skills.

4. Should I send a thank-you note after my Packaging Development Supervisor interview?

Yes, sending a thank-you note after your Packaging Development Supervisor interview is highly recommended. It shows professionalism and gratitude for the opportunity. Aim to send the note within 24 hours of your interview. Personalize it by mentioning specific topics discussed during the interview and reiterating your enthusiasm for the position. This not only reinforces your interest but also helps you stand out among other candidates.