Embarking on a career as a mechanical technician promises a pathway rich with opportunities and a role at the heart of various industries. From automotive companies to manufacturing units, mechanical technicians are the lifeline ensuring that systems run smoothly and efficiently. Before you can don the hat of a mechanical technician, there is a vital step that you need to cross — the interview stage.

As you set your sights on landing that dream job, equipping yourself with knowledge and insights into the most asked questions during a mechanical technician interview will stand you in good stead. In this guide, we will help you navigate this critical stage with a detailed breakdown of the top 21 mechanical technician interview questions, coupled with expert answers. So, let’s set the stage and propel you one step closer to your dream job!

- Top 21 Mechanical Technician Interview Questions and Answers (With Samples)

- 1. Can you tell us about a challenging problem you encountered in a previous role and how you handled it?

- 2. How do you ensure maintenance and safety protocols are followed in your daily activities?

- 3. Can you explain the importance of preventative maintenance?

- 4. What measures do you take to keep up-to-date with the latest developments in the mechanical field?

- 5. Can you describe an instance where you successfully improved a process or system?

- 6. How do you go about diagnosing a mechanical failure?

- 7. What steps do you take when installing new mechanical systems?

- 8. Can you discuss a time when you had to work as part of a team? How did you contribute?

- 9. How familiar are you with 3D modeling and simulation software? Can you give examples of when you have used them?

- 10. Describe a project where you were responsible for maintaining documentation. How did you ensure accuracy and completeness?

- 11. What safety protocols do you consider most important when working with heavy machinery?

- 12. Can you give an example of a time you identified a potential hazard and took action to prevent an accident?

- 13. How do you ensure quality control in your work?

- 14. How proficient are you in reading and interpreting mechanical drawings?

- 15. Can you explain the concept of tribology and its relevance in the mechanical field?

- 16. How do you stay motivated during repetitive tasks?

- 17. Describe an instance when you had to adapt quickly to a change in specifications or plans.

- 18. What methods do you employ to diagnose hydraulic system issues?

- 19. What is your experience with predictive maintenance tools, and how have you utilized them in your previous roles?

- 20. How do you prioritize tasks when faced with multiple urgent issues?

- 21. Can you describe a situation where you successfully trained or mentored a junior technician?

- Conclusion

Top 21 Mechanical Technician Interview Questions and Answers (With Samples)

Before we plunge into the heart of the matter, take a moment to assimilate that each question presents an opportunity to showcase not just your technical knowledge, but also your problem-solving ability and your experience in the mechanical field. Let us now delve into these questions one by one, unpacking them to understand what they entail and how best to answer them.

1. Can you tell us about a challenging problem you encountered in a previous role and how you handled it?

This question aims to evaluate your problem-solving skills and your capacity to handle challenges effectively.

Sample Answer

“In a previous role at a manufacturing firm, we faced a recurring issue with one of our key machines. It was causing a bottleneck in the production line. I took the initiative to meticulously analyze the machine components during downtime, and identified a fault in its motor system. After presenting my findings, we replaced the faulty part, enhancing efficiency and resolving the bottleneck.”

2. How do you ensure maintenance and safety protocols are followed in your daily activities?

This question explores your adherence to safety regulations and how seriously you take maintenance routines.

Sample Answer

“To ensure adherence to maintenance and safety protocols, I always start with a thorough understanding of the guidelines set by the company. I make it a point to perform regular checks and follow a systematic maintenance schedule, keeping meticulous records of each activity. Moreover, I actively engage in safety drills and workshops to stay abreast of the best practices.”

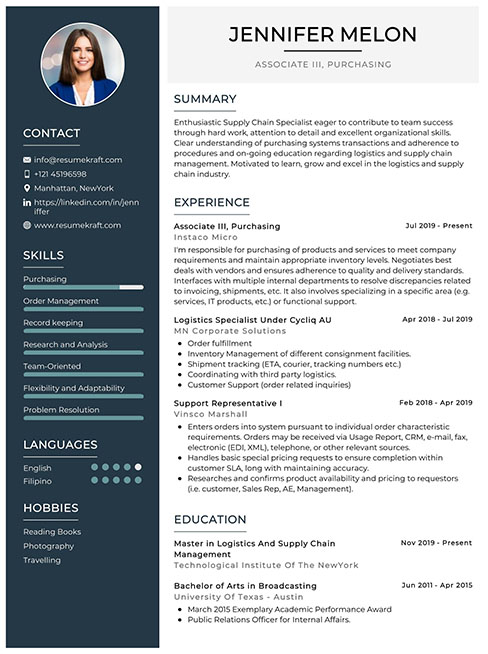

Build your resume in just 5 minutes with AI.

3. Can you explain the importance of preventative maintenance?

Understanding the critical role of preventative maintenance is key in a mechanical technician role.

Sample Answer

“Preventative maintenance is pivotal in averting unexpected breakdowns and ensuring the longevity of equipment. It involves regular inspections, servicing, and repairs to nip potential issues in the bud before they escalate into major problems. This proactive approach not only maintains the optimal functioning of machinery but also saves time and resources in the long run.”

4. What measures do you take to keep up-to-date with the latest developments in the mechanical field?

This question is designed to assess your passion for learning and your commitment to staying updated in your field.

Sample Answer

“I am a firm believer in continuous learning. I regularly attend webinars and workshops, and follow prominent industry journals and forums to stay updated with the latest developments. Additionally, I am a member of a few online communities where professionals share experiences and knowledge, aiding in my personal and professional growth.”

5. Can you describe an instance where you successfully improved a process or system?

The interviewer wants to gauge your ability to enhance existing processes or systems, showcasing your proactive approach.

Sample Answer

“In my previous role, I noticed that the workflow had room for improvements to increase efficiency. I mapped out the existing process and identified areas of waste and redundancy. I then proposed a revised workflow that streamlined operations by introducing parallel processing in some stages, which was implemented and resulted in a 20% increase in productivity.”

6. How do you go about diagnosing a mechanical failure?

Your diagnostic skills are put to the test here, showcasing your systematic approach to identifying and solving issues.

Sample Answer

“To diagnose a mechanical failure, I begin with a detailed inspection to understand the symptoms clearly. I employ a systematic approach, isolating different components to identify the source of the failure. Utilizing both manual inspection techniques and diagnostic tools, I gather data to pinpoint the issue. Once identified, I focus on finding the most efficient solution, always keeping safety and effectiveness in mind.”

7. What steps do you take when installing new mechanical systems?

This question delves into your expertise in installing new systems, focusing on the meticulous attention to details necessary in the process.

Sample Answer

“When installing new mechanical systems, the initial step is to thoroughly review the technical specifications and requirements. Following this, I ensure that the installation site is prepared appropriately, taking into consideration the spatial requirements and safety precautions. During the installation, I adhere strictly to the guidelines, while also ensuring that each component is correctly aligned and calibrated. Post-installation, I perform tests to guarantee the system is operating optimally.”

8. Can you discuss a time when you had to work as part of a team? How did you contribute?

Your teamwork skills are explored here, emphasizing your ability to work harmoniously in

a group setting.

Sample Answer

“In my previous role, I was part of a team responsible for upgrading a series of manufacturing equipment. I took charge of coordinating between various departments to ensure smooth communication. Additionally, I assisted in creating a detailed plan that outlined each member’s responsibilities clearly, fostering a collaborative and efficient working environment.”

9. How familiar are you with 3D modeling and simulation software? Can you give examples of when you have used them?

Your adeptness in modern technological tools is assessed through this question, highlighting your capacity to adapt to technological advancements.

Sample Answer

“I have substantial experience working with 3D modeling and simulation software such as AutoCAD and SolidWorks. In one of my past roles, I utilized SolidWorks to design components, verifying their dimensions and tolerances. Furthermore, I used simulation tools to analyze stress distribution in parts under varying load conditions, aiding in optimized design processes.”

10. Describe a project where you were responsible for maintaining documentation. How did you ensure accuracy and completeness?

Maintaining accurate and complete documentation is vital, and this question explores your organizational and detail-oriented skills.

Sample Answer

“During a plant expansion project, I was tasked with maintaining all documentation, including technical drawings, vendor communications, and project timelines. I implemented a digital documentation system that allowed for real-time updates and easy retrieval of documents. I regularly reviewed the entries for accuracy and completeness, ensuring that all data was correctly logged and up-to-date, which was pivotal in the smooth progress of the project.”

11. What safety protocols do you consider most important when working with heavy machinery?

Safety is paramount, especially when working with heavy machinery, and this question evaluates your knowledge of safety protocols.

Sample Answer

“Safety with heavy machinery involves several protocols such as ensuring proper training for all operators, always using Personal Protective Equipment (PPE), and adhering to lockout-tagout procedures to control hazardous energy. Additionally, regular maintenance and safety audits are crucial in preempting accidents and fostering a safe working environment.”

12. Can you give an example of a time you identified a potential hazard and took action to prevent an accident?

Your proactiveness in identifying and mitigating potential hazards is assessed through this question, underscoring your commitment to safety.

Sample Answer

“In one instance, I noticed a frayed electrical cable near a water source, posing a significant hazard. I immediately isolated the area, notified the concerned departments, and took measures to rectify the issue promptly. This swift action prevented a potential accident, highlighting the importance of always being vigilant about safety.”

13. How do you ensure quality control in your work?

This question delves into your dedication to maintaining high quality in your work, highlighting your attention to detail.

Sample Answer

“Ensuring quality control is a multi-faceted process. It involves following the specified standards rigorously, employing precise measuring tools, and maintaining a keen eye for details. Additionally, I adopt a proactive approach, continuously seeking ways to improve processes and mitigate potential issues before they escalate, thus maintaining a high standard of quality in all tasks.”

14. How proficient are you in reading and interpreting mechanical drawings?

Reading and interpreting mechanical drawings accurately is a vital skill, and this question gauges your proficiency in this area.

Sample Answer

“I am highly proficient in reading and interpreting mechanical drawings. I am familiar with different types of drawings, including assembly drawings, part drawings, and schematic drawings. I can accurately interpret dimensions, tolerances, and symbols used, ensuring that the assemblies and components are fabricated to the specified standards.”

15. Can you explain the concept of tribology and its relevance in the mechanical field?

Your understanding of core mechanical concepts is tested here, showcasing your foundational knowledge in the field.

Sample Answer

“Tribology is the study of friction, wear, and lubrication that occurs between interacting surfaces in relative motion. In the mechanical field, it is immensely relevant as it aids in understanding how to reduce wear and tear, optimize performance, and extend the lifespan of machinery through appropriate material selection and lubrication strategies.”

16. How do you stay motivated during repetitive tasks?

The question explores your motivation levels, focusing on your capacity to remain engaged even during monotonous tasks.

Sample Answer

“To stay motivated during repetitive tasks, I set small goals and challenges for myself, aiming to improve efficiency and reduce errors. Additionally, I maintain a positive mindset, understanding the critical role such tasks play in the larger picture of maintaining machinery efficiency and safety, which drives me to perform them diligently.”

17. Describe an instance when you had to adapt quickly to a change in specifications or plans.

Adaptability is the focus here, with an emphasis on your ability to quickly and successfully adjust to changes.

Sample Answer

“During a facility upgrade project, we received a change in specifications midway. I swiftly realigned our approach, adjusting the timelines and resources accordingly. I also facilitated a smooth communication flow, ensuring all team members were updated and on the same page, thereby successfully adapting to the change without compromising on the project’s integrity.”

18. What methods do you employ to diagnose hydraulic system issues?

Your expertise in diagnosing specific mechanical systems is tested through this question, underscoring your technical skills.

Sample Answer

“To diagnose hydraulic system issues, I utilize a systematic approach beginning with visual inspections for leaks or damages. I then proceed to check the fluid levels and quality, following which I analyze the pump and valve operations for any irregularities. Leveraging diagnostic tools to measure pressure levels and flow rates aids in identifying the exact issue, enabling a targeted and effective resolution.”

19. What is your experience with predictive maintenance tools, and how have you utilized them in your previous roles?

Your experience with modern maintenance techniques and tools is explored through this question, emphasizing your up-to-date knowledge.

Sample Answer

“I have worked extensively with predictive maintenance tools like vibration analysis, infrared thermography, and ultrasound detection in my previous roles. For instance, I employed vibration analysis to monitor the condition of bearings and identify issues before they could escalate, enabling timely interventions and reducing downtime.”

20. How do you prioritize tasks when faced with multiple urgent issues?

Your ability to prioritize tasks effectively in high-pressure situations is assessed here, illustrating your organizational skills.

Sample Answer

“In situations with multiple urgent issues, I prioritize tasks based on their impact on the operations and safety. I perform a quick assessment to determine which issue, if not addressed immediately, would have the most severe repercussions. By systematically addressing the most critical issues first, I ensure minimal disruption to operations while maintaining a safe environment.”

21. Can you describe a situation where you successfully trained or mentored a junior technician?

Your leadership and mentoring skills are the focus in this question, highlighting your capacity to nurture talent.

Sample Answer

“In my previous role, I mentored a junior technician who was new to the field. I developed a structured training plan that covered both theoretical knowledge and hands-on experience. Under my guidance, he quickly grew proficient in various tasks, becoming an integral member of the team. My approach was to foster a supportive and collaborative learning environment, encouraging him to ask questions and learn through practical experience.”

Conclusion

Navigating the intricate pathways of a mechanical technician interview has just become significantly simpler with our detailed guide on the top 21 questions you’re likely to face.

While showcasing your technical prowess is vital, remember that illustrating your problem-solving abilities, your commitment to safety, and your ability to work well in a team are equally important.

This article equips you with an arsenal of ready answers and insights, steering you firmly in the direction of success. As you step into the interview room, remember to articulate not just your knowledge but also your passion for the field, and the dedication you bring to ensuring safety and efficiency in every task you undertake.

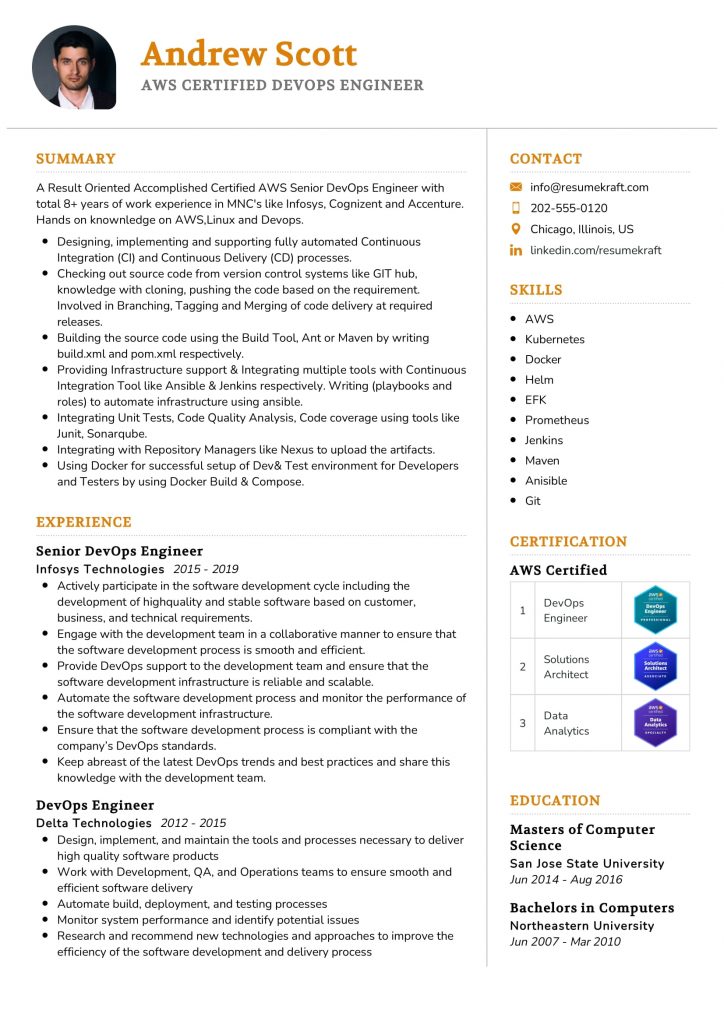

Remember to utilize resources like AI Resume Builder, Resume Design, Resume Samples, Resume Examples, Resume Skills, Resume Help, Resume Synonyms, and Job Responsibilities to create a standout application and prepare for the interview.

Build your resume in 5 minutes

Our resume builder is easy to use and will help you create a resume that is ATS-friendly and will stand out from the crowd.